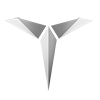

In some personalized RVs, a large number of curved surface designs are often used, most of which are the front and rear panels. How to make a curved panel, one way is to use an open mold to make a whole piece of FRP part, but the FRP part has only one layer, and the thickness is only a few millimeters, although it is beautiful, it has many disadvantages: poor heat preservation effect, easy to break, difficult to repair and expensive. How to solve these problems? TOPOLO uses another simple and efficient approach: curved composite panels.

Curved RV Composite Panels

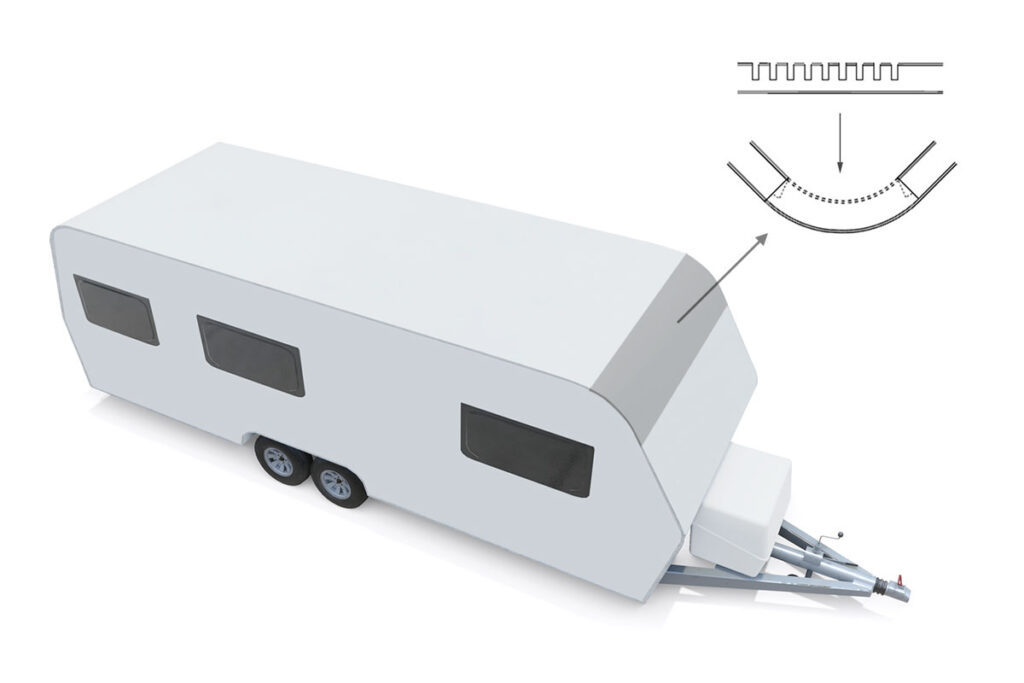

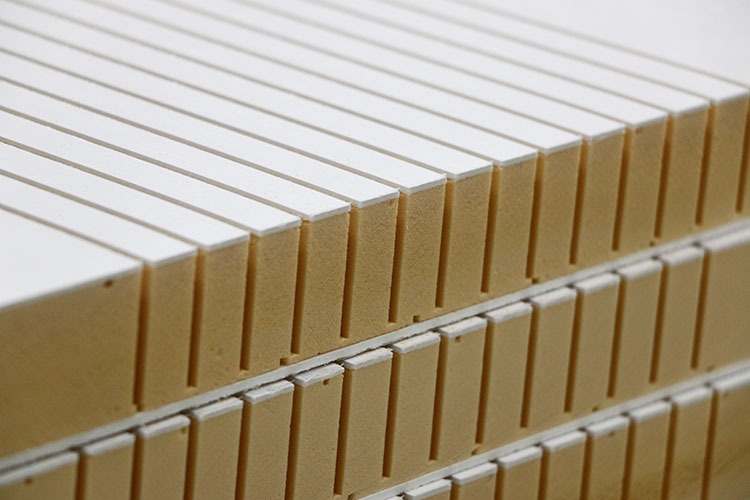

We know that the most popular RV composite panels are FRP laminated foam sandwich panels, but FRP composite panels are flat and straight and cannot be used directly as front or rear panels of a caravan. We cut grooves with a certain depth and width on the FRP composite panel (according to the curvature of the composite panel). So as to make the curved panel we want.

How to efficiently and accurately manufacture curved RV composite panels?

- High-quality Materials

High-quality gel-coat FRP sheets and foam cores. We use high-strength anti-fatigue FRP. After bending, the FRP surface on the inner curved side is still flat and smooth, and no obvious seams can be seen. The foam board uses high-quality closed-cell thermal insulation XPS or PU, which can give the panel enough strength.

CNC Machining

Traditional manual cutting not only has poor precision, but also low efficiency and poor product appearance. CNC machining can achieve high-volume and high-precision production.