Composite RV Boxes

- More Lightweight

- More Stronger

- More Convenient

Why Choose Composite RV Boxes?

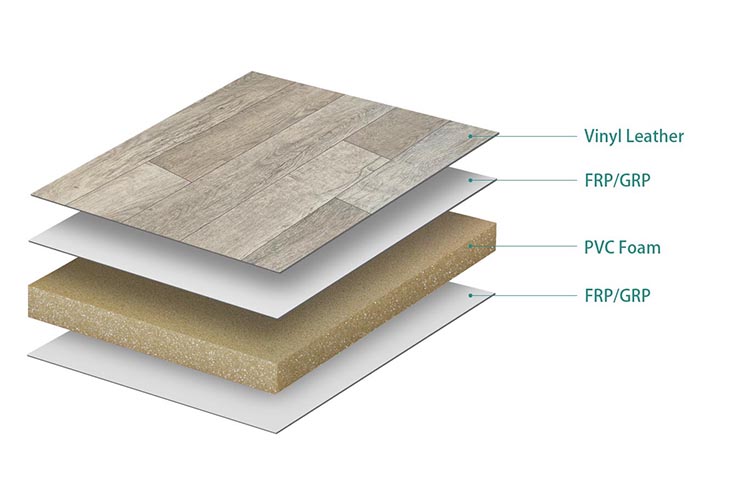

The composite RV box is installed by connecting the sandwich panels of the one-piece forming process. Composite RV boxes have many advantages over RV boxes that use wood and aluminum frame construction and fully molded fiberglass. In short, its light weight, high strength, and simple installation make it more and more popular in RV manufacturers.

What materials are used for composite RV boxes?

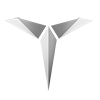

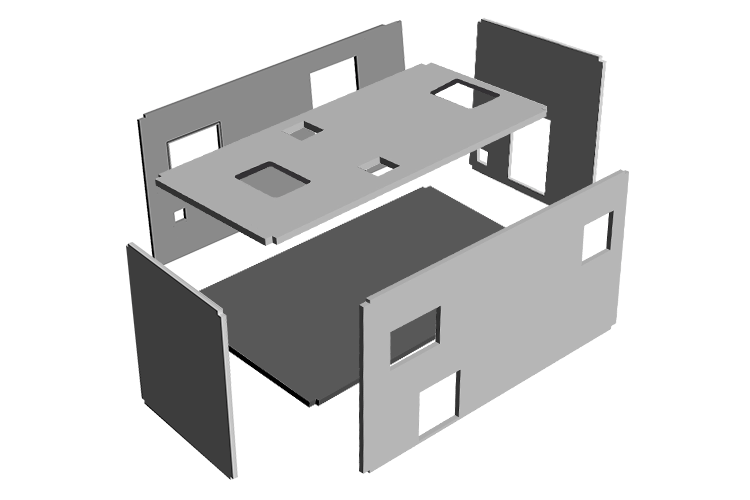

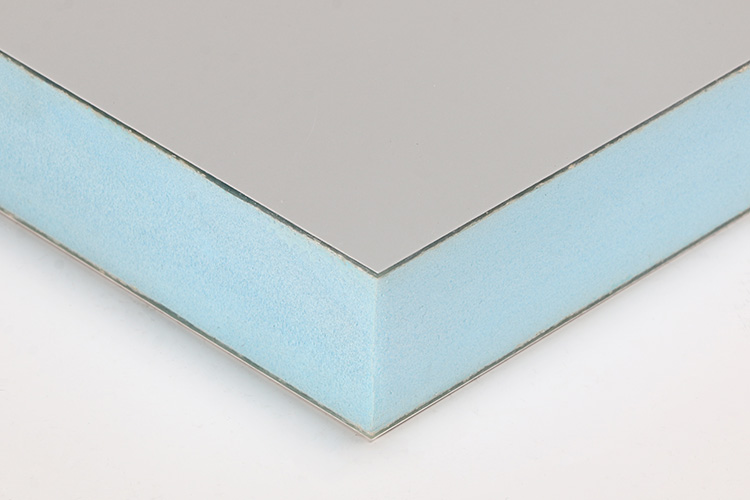

RV composite panel is a kind of foam sandwich board with a stable structure. The metal frame (usually aluminum tube or timber) is embedded inside, and FRP or aluminum is used as the skin. The core material is mostly PU (polyurethane), and XPS (extruded polystyrene). )Foam. Foam materials such as PET (Polyethylene terephthalate), PVC, (polyvinyl chloride) MPP (Microcellular Polypropylene) are also used on some RV boxes. Use professional machines to bond the core material and the skin into one layer with vacuum and chemical glue, and cut or punch holes according to the design.

- Skin: Fiberglass, Aluminum

- Core: XPS, PU, PET, PVC, MPP foam

- Mat: GMT (Glass Mat Thermoplastic – Optional)

- Frame: Aluminum Tube, stainless steel Tube, Galvanized Tube

We custom RV composite boxes are based on your vehicle

Sturdy and strong

We provide a more effective insulating sandwich structure, we use welded embedded metal structure, the embedded structure will not contact the external skin material.

Thermal insulation

The core material of the RV box is closed-cell foam with extremely low thermal conductivity and water absorption. When the temperature reaches minus 30 °C and the interior reaches 50 °C, it still ensures no frost in the RV and avoids humidity and mildew. When heating and cooling are required, more energy consumption is reduced.

Smooth surface

We have a 12m-long sandwich panel processing platform, using a combination of positive and negative pressure molding technology, the surface of the box is both flat and smooth.

Stronger connection

RV Composite panels are connected by custom-made aluminum profiles instead of rivets, and the use of glue is reduced, which makes the installation and disassembly of the RV box easier, and even non-professionals can try to install it.

Multi-point subframe system

In order to securely install the box on the frame, a sub-frame is required. We supply multi-point sub-frames to make the RV box and the chassis perfectly fit together. Even under high-intensity off-road requirements, the structure is still strong, and the box is still not damaged.

Computer analysis

After an effective CAE simulation test, we have the least embedded frame, and the most suitable plate thickness, and retain greater strength, saving costs for customers.

Doors and Windows

We will reserve the positions of doors and windows on the caravan box. Of course, if you want to omit these steps, you can choose to directly install the doors and windows we supply.

Floor Selection

The RV floor is often a neglected part, but it is very important. It is the part that bears the most weight. Bathing, cooking, dining, and walking are all performed on it. It must withstand the attack of oil, water vapor, and chemicals. A bad floor will greatly reduce the comfort of your RV, so it is very important to choose a good floor material.