Camper Furniture Board

- High Strength

- Waterproof

- Lightweight

- High-temperature Resistance

- Environmental Protection

The requirements for the furniture board inside the camper are relatively high. The furniture board must have the characteristics of lightweight, high-temperature resistance, environmental protection, moisture-proof and waterproof. At present, there are many materials for RV furniture on the market, including plywood, solid wood and other composite board materials. There is no doubt that wood is everyone’s favorite furniture material. It makes the environment inside the RV more comfortable and feels more homely. But these wooden furniture will also bring you a lot of trouble. First of all, wood is not waterproof, if moisture enters the wood, your furniture will be damaged. Over time, they will end their service life early. Secondly, these furniture are too bulky, which greatly increases the weight of the camper body and indirectly consumes more fuel. Third, many solid wood furniture boards are expensive and require multiple processing procedures, and the later maintenance is also costly.

Is there any other better option? Of course, the Compact Laminate (HPL) board launched by TOPOLO-RV is an ideal replacement material.

What is HPL board?

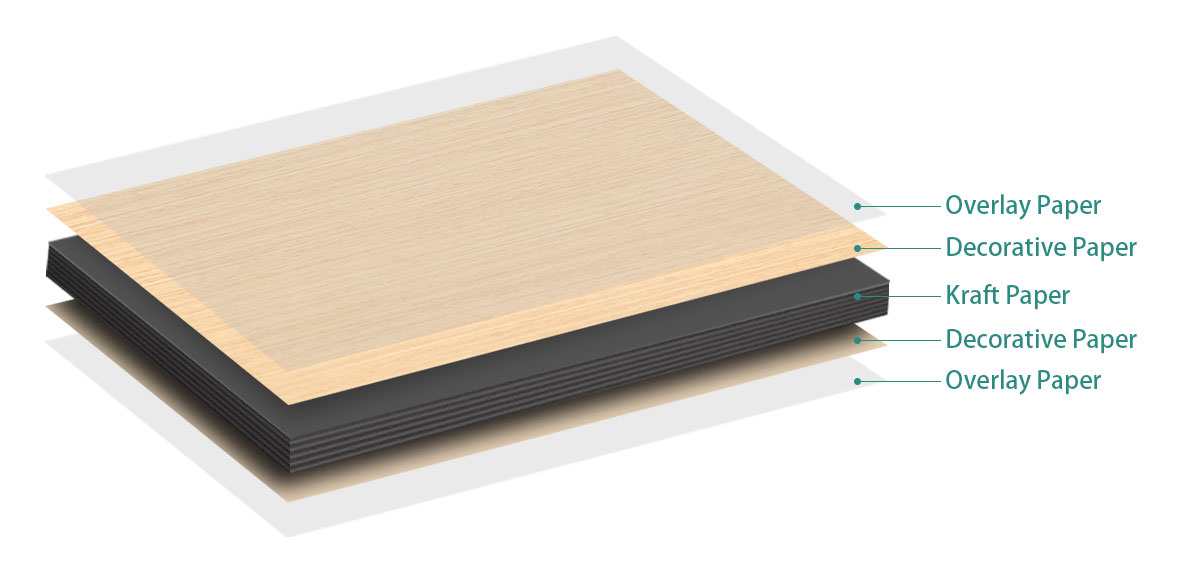

HPL is the abbreviation of High-pressure Laminate. It is made of decorative colored paper containing melamine resin and multiple layers of black or brown kraft paper impregnated with phenolic resin, and then pressed with steel plates in a high-temperature and high-pressure environment. HPL is a refractory material widely used in surface decoration, with rich surface colors, textures and special physical properties.

Features and Benefits of Compact Laminate Furniture Board

- Waterproof and moisture-proof: The water absorption rate of the HPL panel is low, and the high-performance resin makes the two sides of the panel fuse with the core material under high temperature and high-pressure conditions, so that the panel is well protected, and the panel will not be affected by moisture and mildew or rot. And the dimensional stability and processing performance of HPL panels is comparable to hardwood.

- Wear-resistant & scratch-resistant: The unique surface structure makes it have good wear-resistant and scratch-resistant properties, especially suitable for places that require frequent cleaning. Even in high-load use, HPL can maintain the same appearance for a long time.

- Easy to clean: HPL has strong resistance to organic solvents such as acetone, xylene and similar substances. The panel is also resistant to disinfectants, chemical cleaners, juices and dyes, and has no effect on the surface and performance.

- Fireproof: HPL belongs to B-1 class fireproof material. Its surface is in contact with burning cigarette butts without damage. Panels will not catch fire or peel off. All HPL panels perform the same in fire as hardwood, will not melt, drip, explode and remain stable over time.

- Strong nail holding power: The nail-holding power of the HPL board is the same as that of solid wood, and the HPL board can be firmly connected together with nails or screws.

Basic Specifications

| Thickness | 1.6~25mm |

| Surface Treatment | High gloss, Matt, Wood grain, Solid color, Stone pattern,etc |

| Density | 800~1500kg/m³ |

| Moisture Content | 8~14% |

| Fireproof Level | B1 |

| Environmental Protection Level | E1 |

Application of HPL board in Camper Furniture

Tables, cabinets, bed panels, partitions, door panels, etc. in a camper can all be manufactured using compact reinforced furniture board. They have far better performance than solid wood and plywood.

Furniture Board in TOPOLO-RV

Our furniture boards come in a variety of surface colors and patterns.