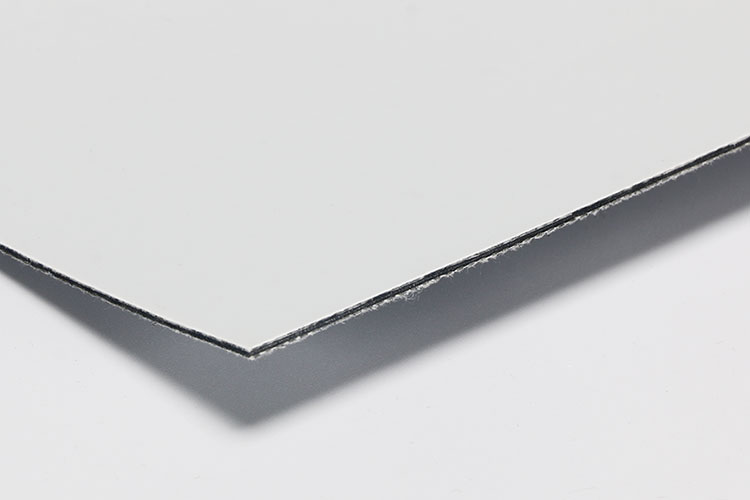

CFRT Sheet is a new type of FRP sheet, which is laminated by multiple layers of continuous fiber reinforced tapes (Unidirectional Tape). CFRT sheets are characterized by a flexible design with a choice of fiber type, fiber content and fiber orientation to meet special requirements. The light weight and high strength of CFRT material, low thickness, plus beautiful appearance, is a breakthrough in the boundaries of traditional metal and plastic materials. Products made of CFRT materials can be recycled at the end of their useful life, and it is a model for sustainable materials.

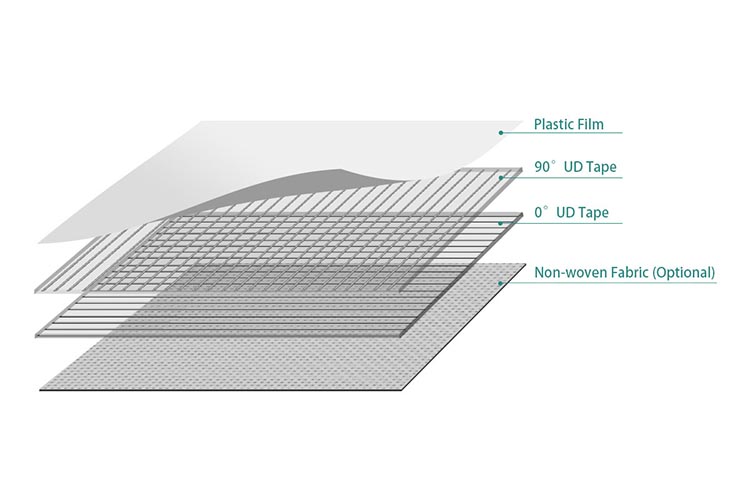

Structure of Laminated CFRT Sheet

- Plastic Film: PET film, PP film, PP film.

- Cross-ply Angle:0/90, 45/45.

- Layers:2~40.

- Total Thickness:0.32~12mm.

- Thickness:300~1200mm.

Fiberglass Unidirectional Tapes

Fiberglass reinforced thermoplastic unidirectional prepreg tape (referred to as UD tape). It is composed of parallel unidirectional fiberglass impregnated with molten thermoplastic resin (PE, PP, PA, etc.).

Basic Technical Parameters of Fiberglass Unidirectional Tapes

| Resin System | Polypropylene(PP); Polyethylene(PE); Polyamide(PA) |

| Tensile Strength | 700~900MPa |

| Density | 1.40~1.60g/cm3 |

| Thickness | 0.20~0.35mm |

| Width | Max 640mm |

| Glass Fiber Content | 55~65% |

| Color | Natural, Black |

| Other Properties | Flame retardant, anti-UV, etc. |

Application of CFRT in RV

As a new RV fiberglass siding material, CFRT is compatible with many existing plastic core systems, such as closed cell foam and honeycomb core. CFRT for RV wall panels is often composited with XPS, PET, PU, PVC foam or PP honeycomb.