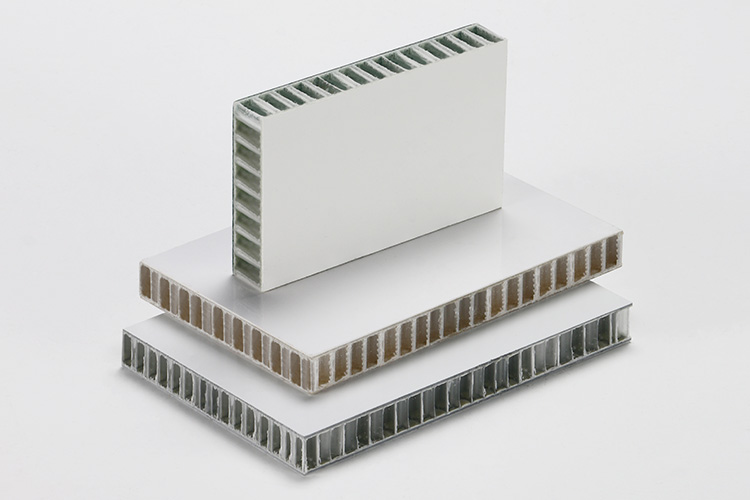

A large number of honeycomb panels are used in many RVs, among which fiberglass polypropylene honeycomb panels are mostly used. Foam core sandwich panels are not the only choice for RVs. If you do not have high requirements for the insulation performance of RV wall panels, but you need a high-strength composite panel instead of foam panels, then fiberglass honeycomb panels are a good choice.

Lightweight & Strong Structure

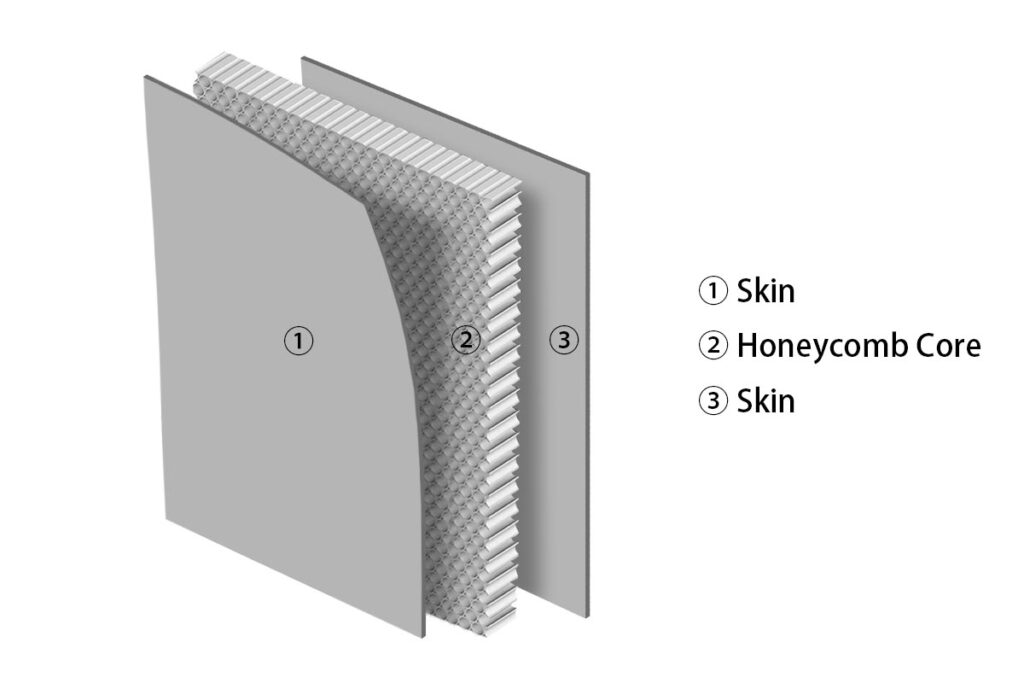

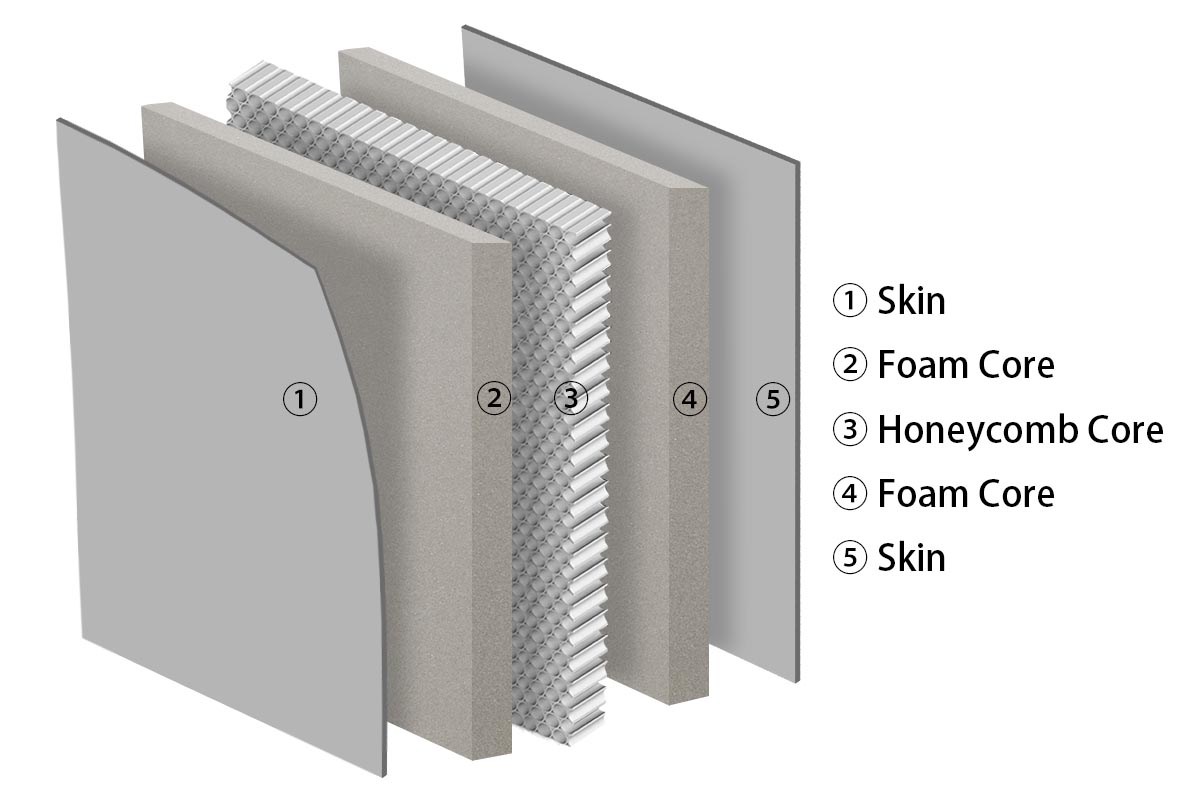

The core material of the fiberglass honeycomb panel is high-quality PP honeycomb, and the high-strength thermosetting FRP or thermoplastic CFRT (continuous fiberglass reinforced thermoplastic) is used as the surface material. The panel is not only strong but also light. We use a unique thermal fusion process to fuse the panels and core materials together, and the panels will not crack during long-term use.

- Skin: FRP or CFRT Sheet

- Core: PP Honeycomb Core

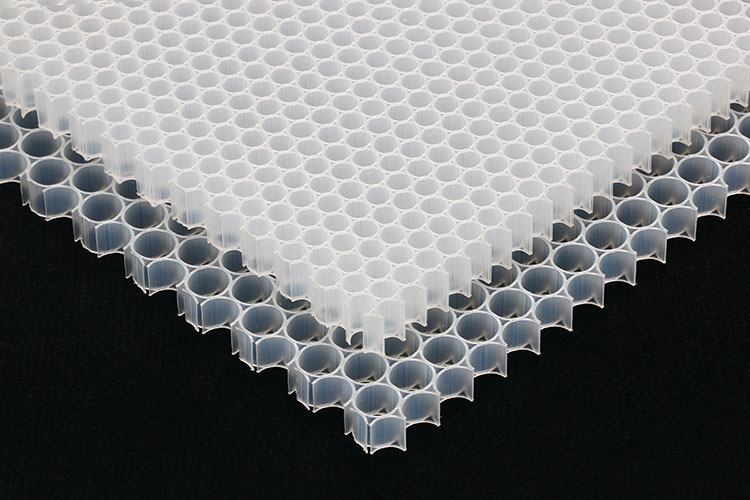

PP Honeycomb Core

Polypropylene (PP) is a general-purpose plastic with stable properties, excellent chemical resistance, high purity, low water absorption and good electrical insulation. In addition, PP material is not only light in weight, but also suitable for welding. Therefore, it is an ideal lightweight honeycomb core material.

Parameters of PP Honeycomb Core

| Item | PP6 | PP8 | PP10 | PP12 | PP16 |

| Cell size(mm) | 6 | 8 | 10 | 12 | 16 |

| Density(kg/m3) | 85 | 80 | 75 | 70 | 80 |

| Compression strength(Mpa) | 1.8 | 1.66 | 1.58 | 1.47 | 1.85 |

| Compression modulus(Mpa) | 50.8 | 45.7 | 41.2 | 38.9 | 50.4 |

| Shear strength(Mpa) | 0.68 | 0.5 | 0.45 | 0.4 | 0.55 |

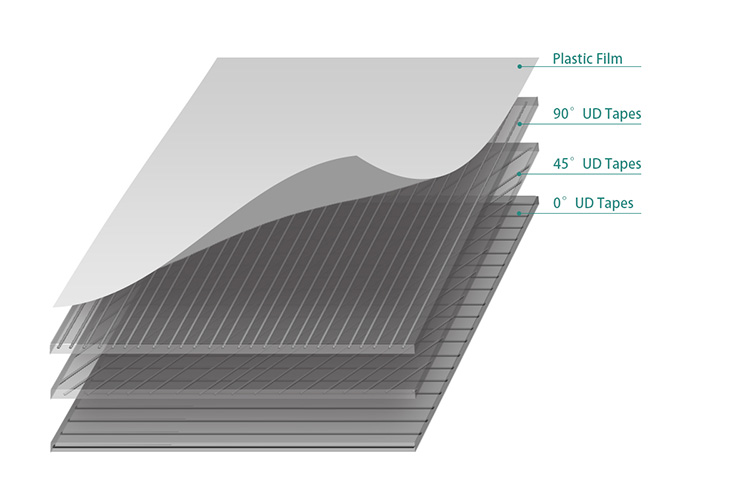

CFRT Sheets

CFRT Sheet is a new type of FRP sheet, which is laminated by multiple layers of continuous fiber reinforced tapes (Unidirectional Tape). CFRT sheets are characterized by a flexible design with a choice of fiber type, fiber content and fiber orientation to meet special requirements. The light weight and high strength of CFRT material, low thickness, plus beautiful appearance, is a breakthrough in the boundaries of traditional metal and plastic materials. Products made of CFRT materials can be recycled at the end of their useful life, and it is a model for sustainable materials.

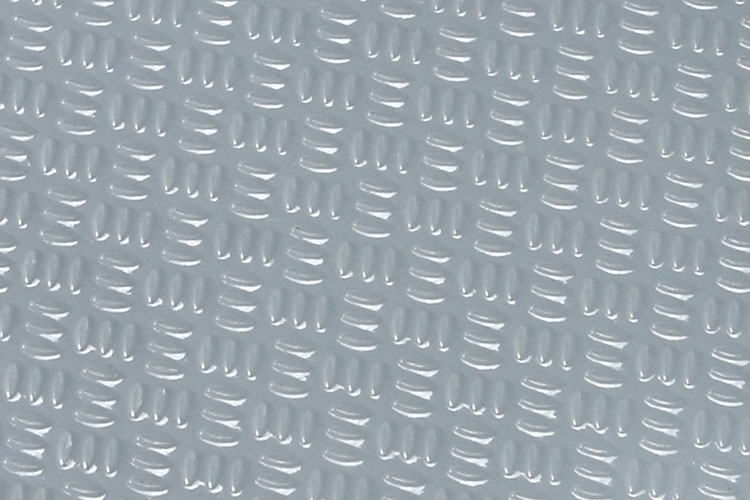

Surface Treatment of RV Honeycomb Panels

The surface of the honeycomb panel can be processed into various textures, colors and patterns, such as high-gloss surface, matte surface, non-slip texture, stone texture, wood grain, etc., which are customized according to customer requirements.

Other Applications on The RV

The application of fiberglass honeycomb panels in RVs is not limited to wall panels, it can also be used in floors, furniture, accessories, etc. of RVs. For example, vinyl floor leather is bonded to its surface to become a light and strong RV floor; the anti-slip texture is hot-pressed on its surface to make it an excellent RV step; the edge-wrapped honeycomb panel is an ideal material for RV interior tables and cabinets.

What Types of RVs are Fiberglass PP Honeycomb Core Panels Suitable for?

The RVs suitable for honeycomb core wall panels are more concerned about lightness and high strength, but they are not satisfactory in terms of heat preservation and waterproofing. Almost any small camper can be considered it, such as teardrop RV, mini off-road trailer. If your RV is going to be camping in a cold area, we recommend foam core wall panels.