MPP sandwich panel is a newly developed FRP/aluminum skin composite panel for RV. It is lightweight, high-strength and has excellent impact resistance. It can effectively replace traditional foam composite panels such as XPS, PU, PET, PVC and EPP.

Basic Specifications of MPP Sandwich Panels

| Skin Material | Gelcoat FRP sheet, Aluminum sheet |

| Core Material | MPP Foam |

| Width | ≤ 3.2m |

| Length | ≤12m |

| Total thickness | 10~120mm (skin: 0.7~5.0mm) |

What is MPP foam?

MPP (Microcellular Polypropylene) is a closed-cell polypropylene (PP) thermoplastic foam material with a cell size of less than 100 μm. It is produced using supercritical fluid foaming technology and is a renewable polymer foam.

Advantages of MPP foam

- Rigidity and Toughness: Existing foam materials are either hard and brittle, or soft and tough, and it is difficult to have both rigidity and toughness. The microporous polypropylene foam material has both rigidity and toughness, which complements the deficiency of the performance of the existing foam material.

- Environmental Protection: The MPP foaming process is clean and pollution-free, and it can be recycled and reused. It is an environmentally friendly product.

- High Temperature Resistance: The thermal deformation temperature of PP foam material is much higher than that of PS and PU foam materials.

- Thermal Insulation: The micron-sized cells effectively reduce the convection of gas in the foam, thereby effectively reducing the heat transfer caused by air convection.

- Lightweight: The density of MPP foam is generally below 50kg/cm³, and the lower density greatly reduces the weight of the RV.

- Waterproof: Micron-sized cells make it extremely low water absorption.

Physical Properties of MPP Foam

| Cell Size | 1~10micron |

| Density | 30~120kg/m³ |

| Heat Distortion Temperature | 60~100°C |

| Thermal Conductivity | 0.04~0.08W/m·K |

| Water Absorption | ≤0.5% |

Mechanical Properties of MPP foam

| Density Magnification | 10 | 15 | 20 | 25 |

| Density(g/cm³) | 90 | 60 | 45 | 36 |

| Compressive Strength(Mpa) | 0.45 | 0.30 | 0.25 | 0.18 |

| Bending Strength(Mpa) | 0.8 | 0.68 | 0.44 | 0.36 |

| Flexural Modulus(Mpa) | 30 | 25 | 20 | 15 |

| Hardness(HC) | 81 | 70 | 66 | 55 |

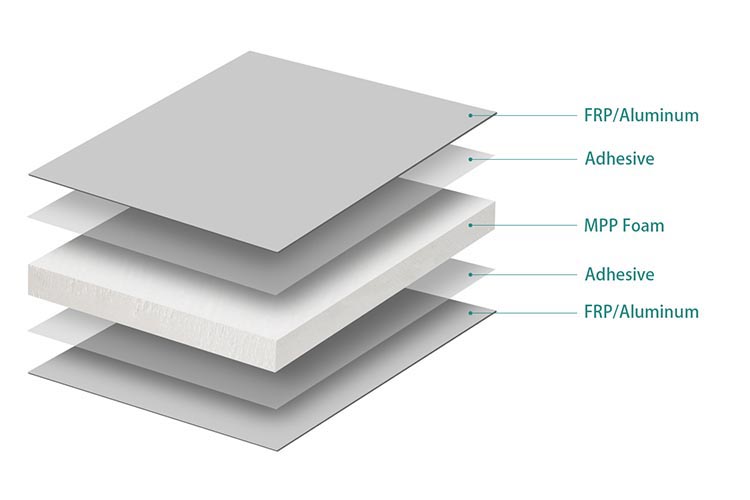

Basic Structure of MPP Sandwich Panels

The skin of the MPP sandwich panel used for the RV is mostly FRP or aluminum sheets, which is compressed and molded together with the MPP foam using special glue as the adhesive.

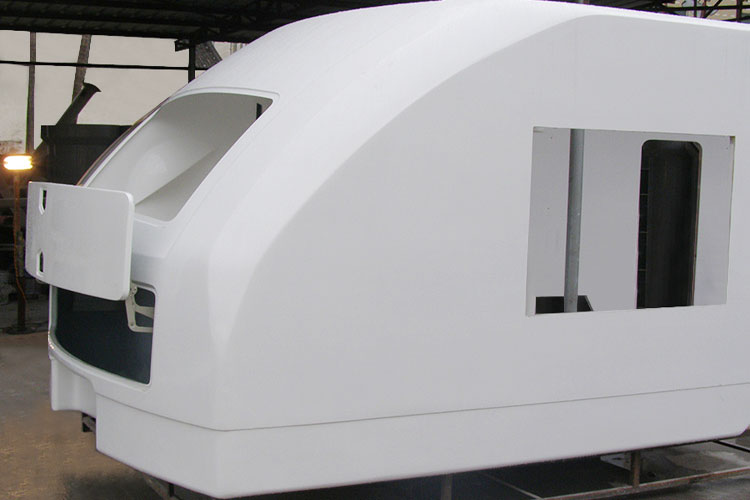

Application of MPP Sandwich Panels in RV

The advantages of using MPP sandwich panels as caravan wall panels are very obvious. The only disadvantage is that its price is much higher than that of XPS, PU, PET, PVC sandwich panels.