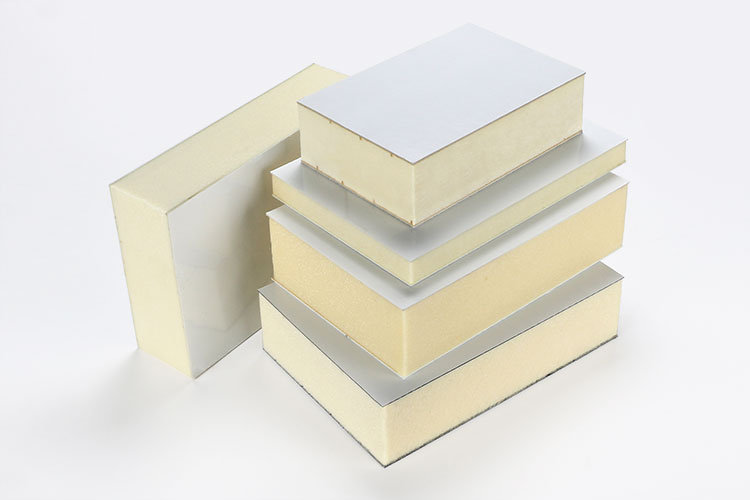

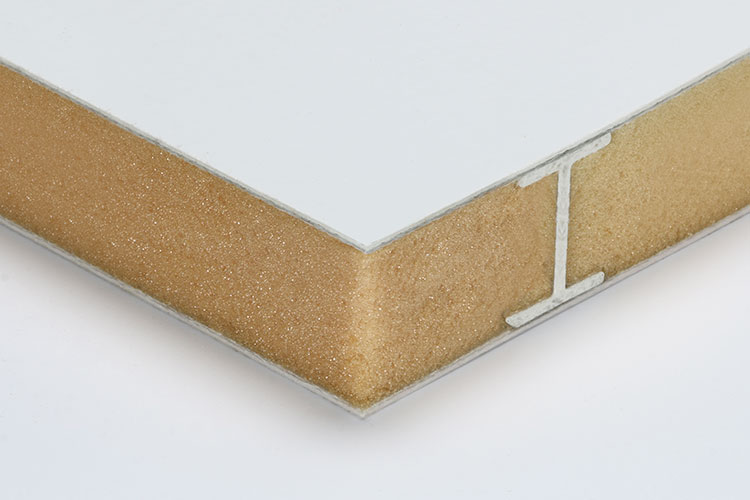

Foam core RV panels with many advantages, it is light, high strength, sound insulation, thermal insulation. The application of closed-cell foam board makes the RV better waterproof and waterproof. Foam board is the most commonly used filling material for RV wall panels. The core material is usually XPS, PU, PVC, PET foam board, etc. Most foam boards have thermal insulation and waterproof properties. Core and skin are bonded together with high-performance glue. In order to increase the strength of rv wall panels, most of the foam core sandwich panels are usually embedded with some reinforced structural components, such as aluminum tubes, steel tubes, wood boards, plastic tubes, etc.

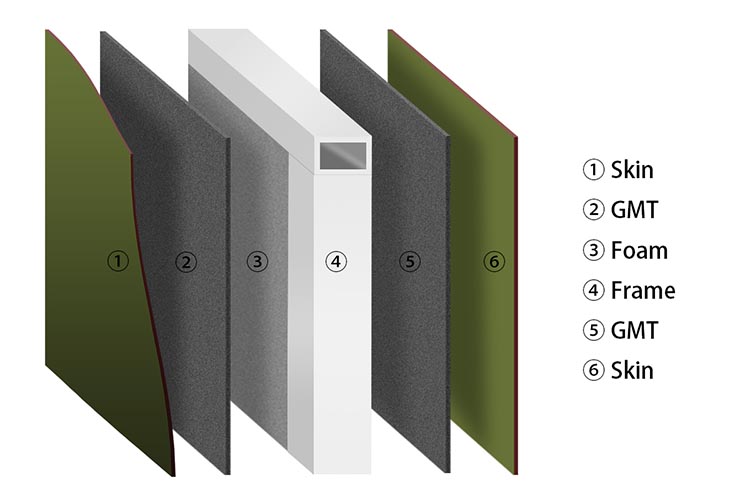

Structure of Foam Core RV Panels

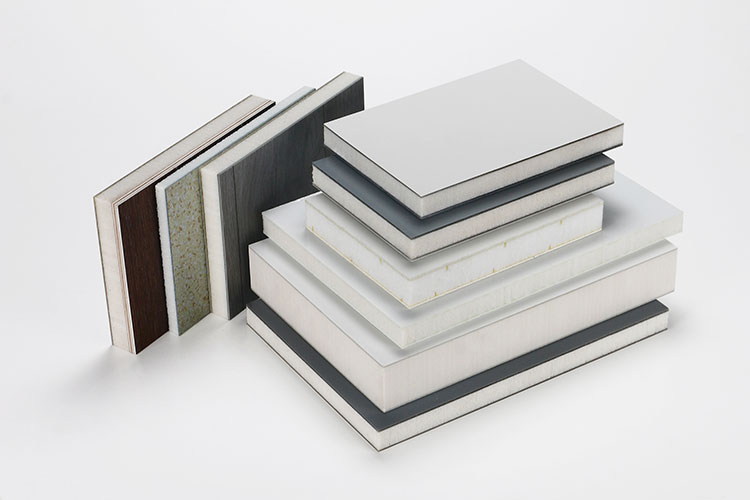

- Skin: FRP Sheets, Aluminum Sheet, Plywood.

- Core: XPS (extruded polystyrene); PET (Polyethylene terephthalate); PVC(polyvinyl chloride); PU (polyurethane).

- GMT Layer: Using GMT (Glass Mat Thermoplastic) as an insulating layer can enhance the strength of the RV panel and its surface smoothness.

Foam Core RV Panel Manufacturing Experts

TOPOLO-RV is committed to providing customers with lightweight solutions. Our foam core composite sandwich panels are used in various types of RVs such as C class motorhomes, off-road trailers, adventure vehicles, teardrop campers, truck campers, caravans, etc. We serve the global market and our customers are all over the world. We will provide a series of customization services for your RV wall panels, including thickness, density, color, shape, surface treatment of the panel.

Advantages of TOPOLO Foam Core RV Wall Panels

Closed Cell Foam Core

The foam core board with a closed cell rate of more than 95% has extremely low thermal conductivity and water absorption, which can prevent moisture from entering the caravan and maintain a constant temperature inside the caravan.

Fiberglass RV Siding

The FRP sheet on our RV siding is coated with yacht-grade gel coat, which will not cause fading and chalking after long-term use, and the color and texture of the surface can be customized.

No Delamination

We use high-quality polyester adhesives and lamination technology combining positive and negative pressures, the foam and skin materials are tightly bonded, and will not delaminate and deform under the extreme weather with the lowest minus -40~+80℃ .

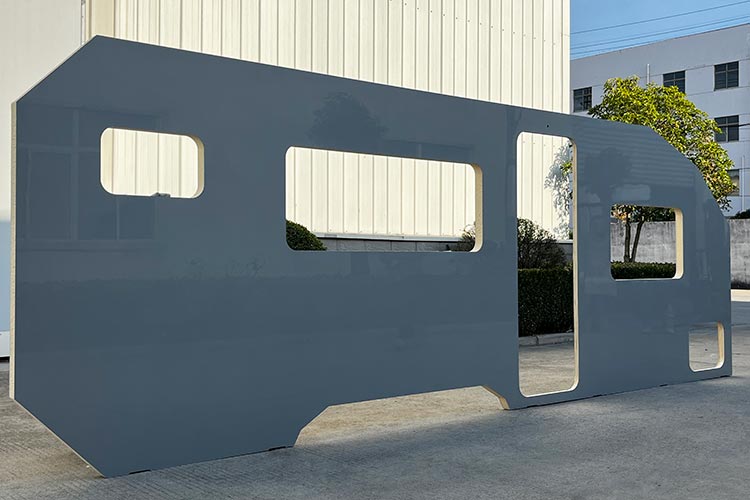

One-piece Molding

We will reserve the position of doors and windows on the wall panels, customers do not need to cut again, and only need to use simple tools to install after receiving the panels.

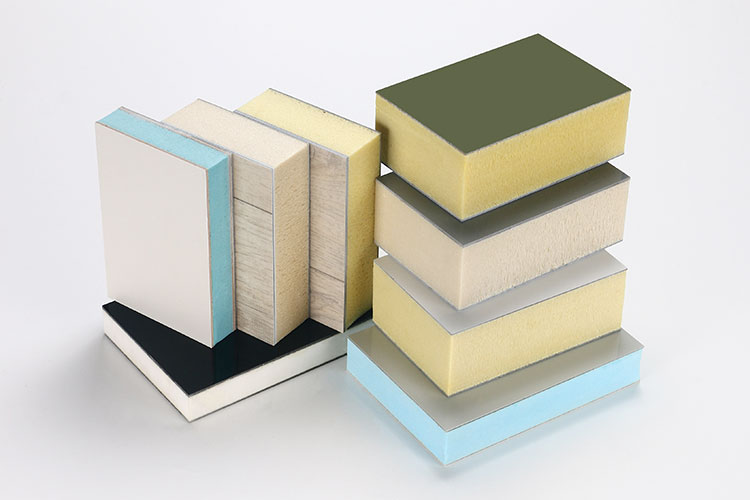

Types of Foam Core RV Wall Panels We Offer

XPS Foam Core Sandwich Panels

- Width: Max 3.2m

- Skin Thickness: 0.7~5.0mm

- Core Thickness: 25~120mm

- Core Density: 35~45 kg/m3

- Skin Materials:FRP Sheets, Aluminum Sheets, Plywoods.

PU Foam Core Sandwich Panels

- Width: Max 3.2m

- Skin Thickness: 0.7~5.0mm

- Core Thickness: 25~120mm

- Core Density: 35~45 kg/m3

- Skin Materials:FRP Sheets, Aluminum Sheets, Plywoods.

PET Foam Core Sandwich Panels

- Width: Max 3.2m

- Skin Thickness: 0.7~5.0mm

- Core Thickness: 25~120mm

- Core Density: 50~300 kg/m3

- Skin Materials:FRP Sheets, Aluminum Sheets, Plywoods.

PVC Foam Core Sandwich Panels

- Width: Max 3.2m

- Skin Thickness: 0.7~5.0mm

- Core Thickness: 25~120mm

- Core Density: 45~250 kg/m3

- Skin Materials:FRP Sheets, Aluminum Sheets, Plywoods.

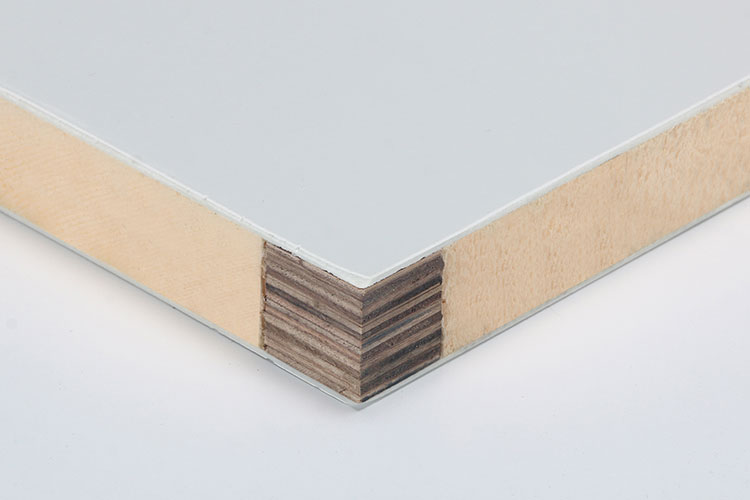

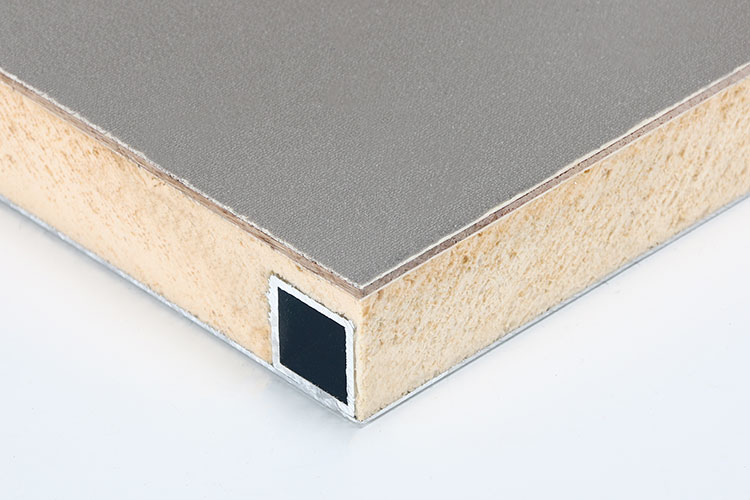

Embedded Reinforced Structural Materials

The foam core caravan panel with too large area will deform due to its own weight, and even break in severe cases. In order to improve the strength of the foam panel and reduce its deformation, some reinforcing structural materials are usually pre-embedded inside the foam, such as aluminum tubes, wood boards, plastic tubes, steel tubes, etc. This not only improves the strength of the panel, but also facilitates the installation of screws and the layout of electric wires.

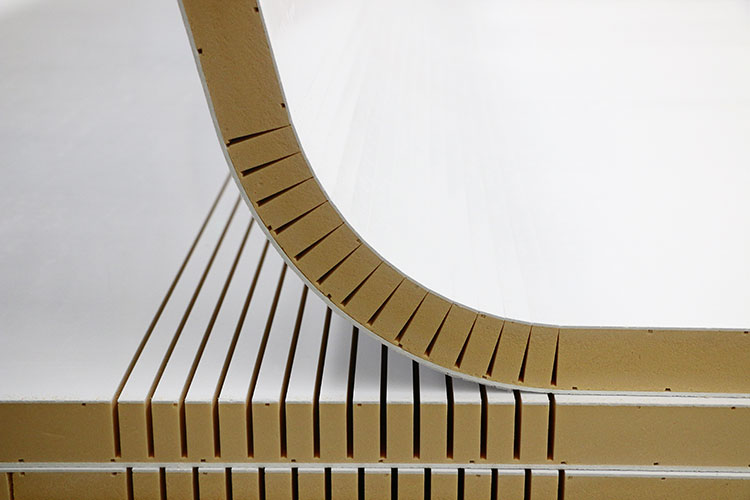

Curved RV Composite Panels

In some personalized RVs, a large number of curved surface designs are often used, most of which are the front and rear panels. How to make a curved panel, one way is to use an open mold to make a whole piece of FRP part, but the FRP part has only one layer, and the thickness is only a few millimeters, although it is beautiful, it has many disadvantages: poor heat preservation effect, easy to break, difficult to repair and expensive. How to solve these problems? TOPOLO uses another simple and efficient approach: curved composite panels.

Applications of Foam Core RV Panels

Foam sandwich panels can be used on almost any type of RV, such as C-class motorhomes, caravans, off-road vehicles, expedition vehicles, truck campers, and even hard-shell Rooftop tents.