Fiberglass RV Siding

Better Protect Your RV

As the outermost protective layer, the RV siding is the most direct factor affecting the service life, so choosing the right caravan siding is also crucial for building a RV. There are many materials on the market that can be used as siding, which material to choose depends on the customer's actual needs for the RV and the consideration of cost performance. Unlike traditional wood and aluminum siding, fiberglass RV siding is gaining popularity and has many advantages that make it stand out.

Basic Specifications

| Fiberglass Type | Fiberglass Mat,Fiberglass Cloth,Continuous Fiberglass | |||||||||||||||||

| Resin Material | Unsaturated Polyester, Vinyl Ester, Epoxy Resin, Polyamide, Phenolic, Polypropylene, Polyethylene, etc | |||||||||||||||||

| Surface Treatment | Gelcoat, Laminated Film | |||||||||||||||||

| Temperature Tolerance Limits | -40ºC to +80ºC | |||||||||||||||||

| Anti-ultraviolet Rate | More Than 99% | |||||||||||||||||

| Warranty | 10~15 years | |||||||||||||||||

| Shape | Sheet or Rolls | |||||||||||||||||

| Length | ≥100m | |||||||||||||||||

| Width | ≤3.2m | |||||||||||||||||

| Thickness | 0.7~5.0mm | |||||||||||||||||

Why Choose FRP Sheets as RV siding?

• Lightweight and High Strength

The relative density is between 1.3~2.0g/cm³, only 1/4~1/5 of carbon steel, but the tensile strength is close to or even exceeds that of carbon steel, and the specific strength can be compared with advanced alloy steel.

• Thermal Insulation

The thermal conductivity of most FRP sheets is lower than 0.23W/m2.K, which cannot be achieved by aluminum materials.

• Anti-corrosion

FRP is a good corrosion-resistant material, and it has good resistance to the atmosphere, water, and general concentrations of acids, alkalis, salts, and various oils and solvents.

• Easy to Repair

There is no obvious trace after the surface repair of FRP, while the aluminum sheet is basically irreparable after damage.

• Aesthetic Performance

The surface of FRP with gel coat coating is flat and smooth, and the coating color can be changed according to customer preferences.

We supply fiberglass RV siding in three different structures:

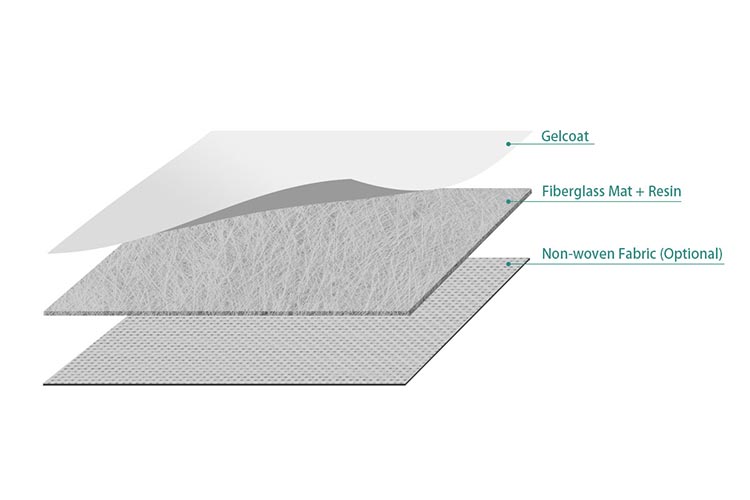

Fiberglass Mat FRP Sheets

The arrangement of chopped glass fibers is random, and it has good cost performance. Sometimes, in order to better integrate with the foam system, a layer of non-woven fabric is pasted on the bottom.

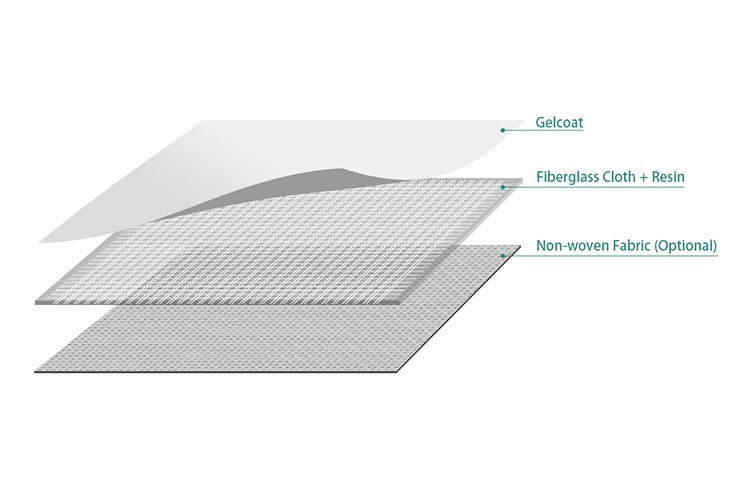

Fiberglass Cloth FRP Sheets

Glass fiber yarns are interwoven in 90° direction, which can increase the ultimate tensile strength and flexural strength of the FRP layer, and the sheet made of glass fiber cloth is smoother.

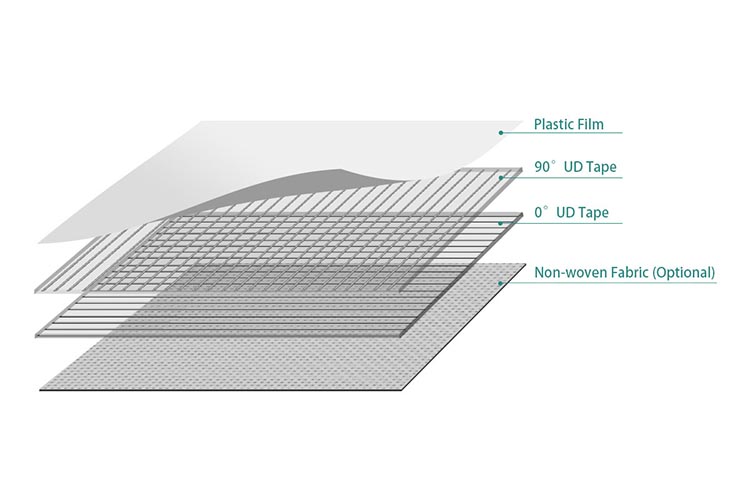

Continuous Fiber FRP Sheets

We call it CFRT (continuous glass fiber reinforced thermoplastic), continuous fiber and resin are combined to form glass fiber unidirectional prepreg tape (UD tape), and multi-layer UD tape is thermally composited into CRRT sheet at different angles material (0°, 45°, 90°). CFRT sheets are definitely stronger.

About Gelcoat FRP Sheets

Gelcoat resin is a kind of unsaturated polyester resin, its main function is to protect the surface and structural layer of FRP sheet. Due to the shrinkage of the polyester resin during the curing process, this will cause the fiberglass texture to protrude on the surface of the FRP sheet. This is very unfavorable for some products with high surface quality requirements. In order to improve the surface quality of the panel and prolong its service life, a layer of gelcoat with high resin content is usually made on the surface of the FRP sheet.

Personalized Surface Treatment

The color of the gel-coated fiberglass RV siding is colorful, you can choose from the RAL color series, and its surface is not a monotonous high-gloss or matte flat surface, we will customize various surface textures and patterns according to customer needs .

Customize Your RV Siding

TOPOLO-RV customizes flat FRP sheets of different specifications for your RV siding, the maximum width can reach 3.2mm, the thickness ranges from 0.7~5.0mm, and there are different personalized surface treatments.

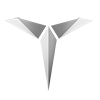

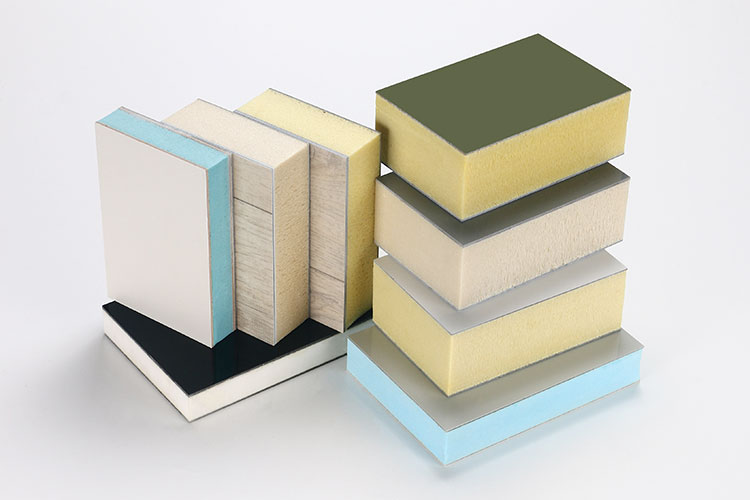

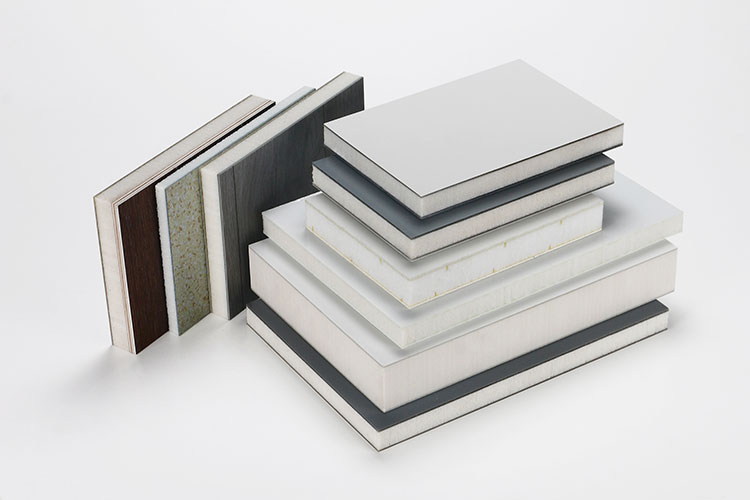

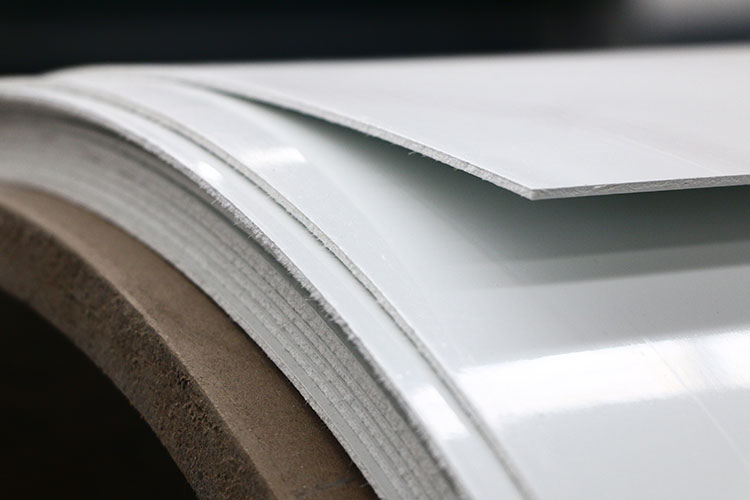

FRP Composite Panels

FRP sheets are compatible with any core system through different processing techniques, such as closed-cell foam, plastic honeycomb core, plywood and so on. FRP composite panels are undoubtedly the most reliable composite panel choice for most RVs.