Computer Numerical Control (CNC) is a method of automatically controlling a machine tool by using software embedded in a microcomputer connected to the tool. CNC can provide higher precision, complexity and repeatability than manual machining. Other advantages include higher speed, flexibility and higher work efficiency, at the same time it allows milling the shape of the product.

Advantages of CNC Machining

- Higher Security

CNC machining can save lives. The operator of the CNC machine is safely isolated from all sharp parts by a special protective structure. He can still see through the glass what’s going on in the machine tool, but he doesn’t need to go anywhere near the mill or the spindle. At the same time, the operator does not have to touch the coolant.

- Higher Efficiency

Traditional machine tools require constant attention, and each worker can only work on one machine tool. When the CNC era came, the situation changed drastically. One worker can operate multiple machine tools. The operator simply checks for any errors in the program or settings.

- Smaller Error

Traditional machine tools rely on the operator’s proficiency with measuring tools, and of course a good worker can set parts very precisely. However, good operators are few and far between. The CNC system uses a special coordinate measuring probe to determine the coordinate zero point to minimize the setting error.

- Stable Replication

In conventional processing, the accuracy of copied products varies greatly, but after the CNC computer program is set, the movement trajectory of the instrument is always the same, and the same batch of products is almost completely consistent

- Complex Surfaces are Easy to Manufacture

It is almost impossible to manufacture complex surfaces with high precision in the traditional way. It requires a lot of physical labor. The CNC system can automatically set the tool path for any surface.

- Higher Cutting Parameters

Manual operation is simply not possible when the shaft speed reaches 10,000rpm or higher. The CNC operating platform can keep the feed rate stable and prevent vibration during high-speed cutting.

CNC Machining by TOPOLO

- 5-axis CNC, the cutter head can move in horizontal x, y, z axis and 2 rotation axes.

- The operating platform is 3.5m wide, and the cutting speed of the equipment can reach 30m/min.

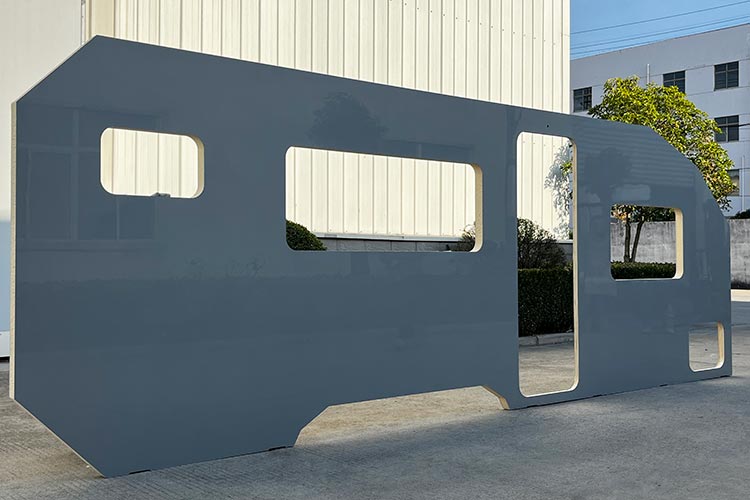

Applicable Specifications for Camper Panels

- Panel structure: The panel is a laminate or sandwich structure, and the outer skin can be 0.7-5.0mm aluminum or FRP. The core material is foam, honeycomb and wood with a thickness of 10~120mm.

- Processing part: The shape and holes (doors, windows, skylights, etc.) of RV composite panels.

- Size: Up to 3000mm*10000mm.