PET foam board is a closed-cell renewable polymer foam that is chemically stable. It has excellent mechanical properties, fatigue resistance, high temperature resistance, low water absorption, and UV resistance. It is basically applicable to all resins and processing techniques, and is an ideal sandwich structure material.

Physical Properties of PET Foam Board

| Items | Unit | Value |

| Density | Kg/m3 | 50~300 |

| Compression Strength | Mpa | 8.5~5.20 |

| Compression Modulus | Mpa | 73~235 |

| Tensile Strength | Mpa | 1.4~4.0 |

| Tensile Modulus | Mpa | 90~275 |

| Shearing Strength | Mpa | 0.55~2.05 |

| Shearing Modulus | Mpa | 13.5~70.0 |

| Closed Cell Rate | % | ≥99 |

| Thermal Conductivity | W/m·K | 0.22~0.25 |

| Water Absorption | % | 0.1~0.3 |

| Operating Temperature | ℃ | ≤100℃ |

Custom PET Foam Boards for Your RV Project

- Thickness:10mm~150mm.

- Width:600mm~1220mm.

- Length:According to customer’s request.

- Color:Blue,Pink,Yellow,White or Customized.

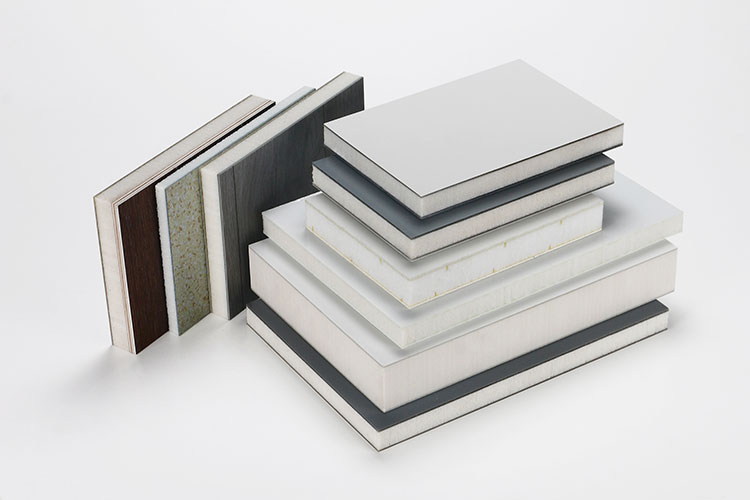

PET Sandwich Panels

Like other types of foam, PET foam board is compatible with a variety of resin systems available, and PET foam changes strength as density increases. Therefore, PET composite panel is a stronger sandwich structure.