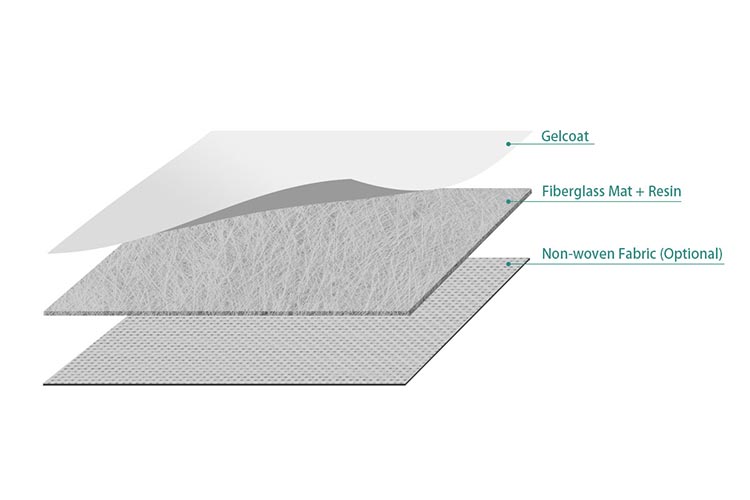

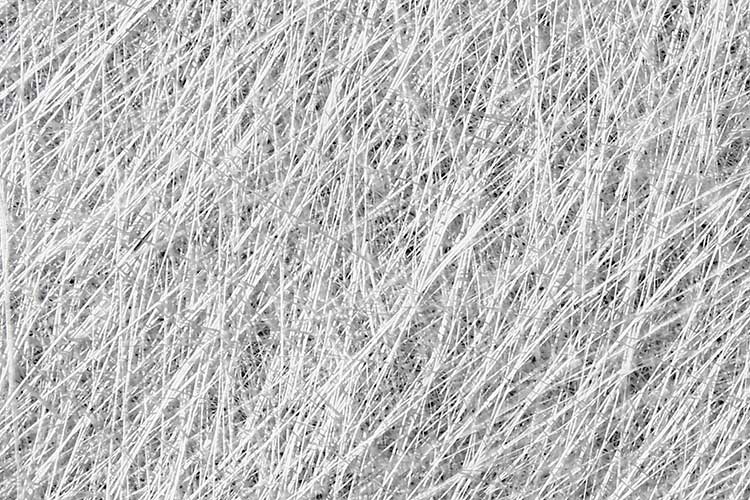

The surface gelcoat of the FRP sheet can be treated with high gloss or matte, customized RAL color system, and various patterns and textures can be pressed. The arrangement of glass fiber mats is random, and they are evenly distributed. Sometimes, a layer of non-woven fabric is pasted on the bottom for better adhesion to the foam system.

Feature of Fiberglass Mat

- The quality per unit area is uniform, which ensures the stability of the glass fiber content and mechanical properties of the product.

- Resin impregnation is fast and consistent, easy to remove air bubbles, and reduces resin consumption and production costs.

Basic Specification

| Thickness | 0.7~5.0mm |

| Width | ≤3.2m |

| Length | ≥100m or Customized |

| Density | 1.3~2.0g/cm3 |

| Fiberglass content | 20~50% |

| Resin system | Unsaturated polyester, vinyl ester, epoxy resin, polyamide, phenolic resin, etc |

| Fiberglass type | Fiberglass Mat |

| Surface treat | High gloss or matte gelcoat |

| Surface color | RAL series |

| Fiber diameter | 9~13μm |

| Tensile Strength | 60~90Mpa |

| Impact Strength | ≥30KJ/㎡ |

| Flexural Strength | 130~180 |

| Water Absorption | ≤0.24% |

| Barcol Hardness | ≥35 |

| R2O content | ≤0.80%. |

| Coupler type | Silanes |

Advantages of Gelcoat FRP Flat Sheets

- Higher cost performance.

- Stable performance and no cracking problems.

- The surface is flat, without obvious fiber texture.