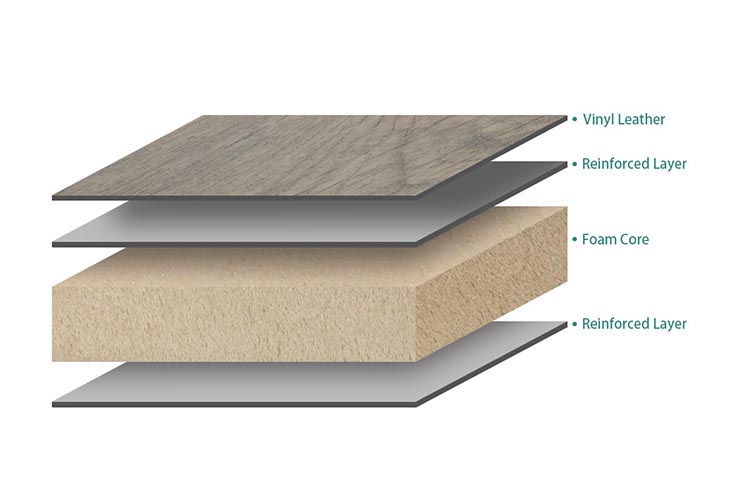

Most of the core materials used in foam core RV floors are rigid closed-cell foams with better thermal insulation effects, such as XPS, PU, PET, PVC foam cores, etc. Its structure is relatively simple, generally using fiberglass, aluminum, or plywood as a reinforcement layer, and a leather-like vinyl floor is used on the top layer. The use of foam will bring many benefits to the RV.

Structure of Foam Core RV Floors

- Upper Skin: Wood grain vinyl leather.

- Upper Reinforced Layer: FRP/Aluminum/Plywood.

- Core: XPS/PU/PET/PVC foam board.

- Bottom Reinforced Layer: FRP/Aluminum/Plywood.

(These reinforcements are sometimes laminated together, or not required.)

Advantages of Foam Core Floor Leather

- Thermal insulation: The thermal conductivity of the foam core is relatively low, especially in winter, which can well ensure that the temperature inside the RV is kept within a certain range.

- Waterproof & Moistureproof: The water absorption rate of closed-cell foam is very low, basically below 1%. In rainy and snowy weather, it is difficult for the floor to penetrate into the interior of the house through the foam core; and the water that accidentally leaks inside the RV , will not cause damage to the floor.

- Noise reduction: Compared with the solid wood floor, the foam core floor can greatly reduce the noise. When you walk on it, it will not make a sound similar to walking on the solid wood floor.