RV Foam Board

Thermal Insulation, Waterproof & Moisture-proof, Lightweight

Thermal insulation is particularly important for a RV. If it is not handled properly, it will cause unbearable heat in summer and terribly cold in winter. Even if an air conditioner or oil heater is installed, it will consume too much energy due to heat loss. With so many different types of insulation on the market, choosing the correct type for each section can be a daunting task. Most RVs use foam board as the core. The advantages of foam core board are good thermal insulation, light weight, shape stability and long service life. In particular, the rigid closed-cell foam board also has excellent waterproof and moisture-proof performance. Commonly used closed-cell foam boards include XPS, PET, PU, PVC, etc.

Thermal Insulation Performance of Different Foam Board Materials

(The following values are for reference only)

| Material | K-value(W/m·K) | R-value @100mm(W/m·K) |

| XPS(Extruded polystyrene) | 0.024~0.034 | 3.03 |

| PU(Polyurethane) | 0.017~0.022 | 4.0 |

| PET(Polyethylene terephthalate) | 0.22~0.25 | 1.67 |

| PVC(Polyvinyl chloride) | 0.06~0.07 | 2.5 |

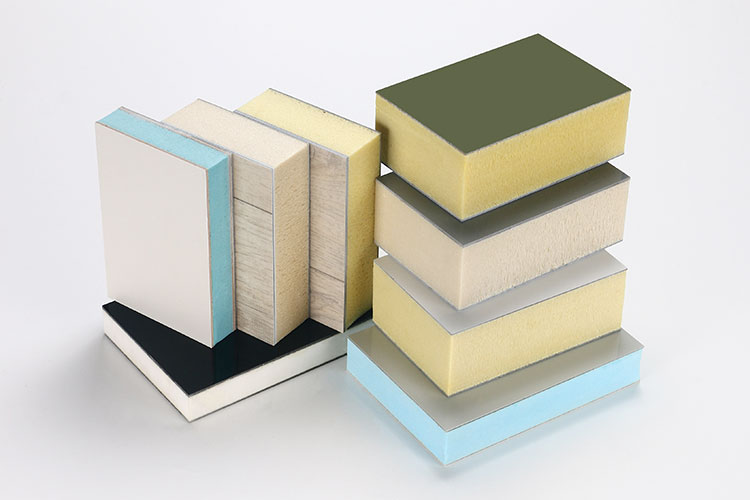

Multilayer Foam Board

Sometimes in order to meet the needs of various applications, a board needs to have comprehensive properties such as thermal insulation, waterproof, and strength. At this time, foam boards of different systems will be bonded together, such as XPS+PVC, PET+XPS and other combinations. The bonds between the foams are very tight and can withstand the test of high and low temperatures.

Application of Foam Board in RV

Foam boards are most commonly used as core materials for walls, roofs, and floors, and are usually laminated with fiberglass, aluminum sheets, or plywood as sandwich panels. In addition, it can also be used as the bed board and skirting board of the RV.

Foam Core RV Panels

The foam core is laminated (using glue as an adhesive) with skin materials (mainly FRP, aluminum) to form a sandwich panel. The application of this composite panel greatly saves the production cost of the caravan, improves the production efficiency, and also makes the caravan more beautiful.