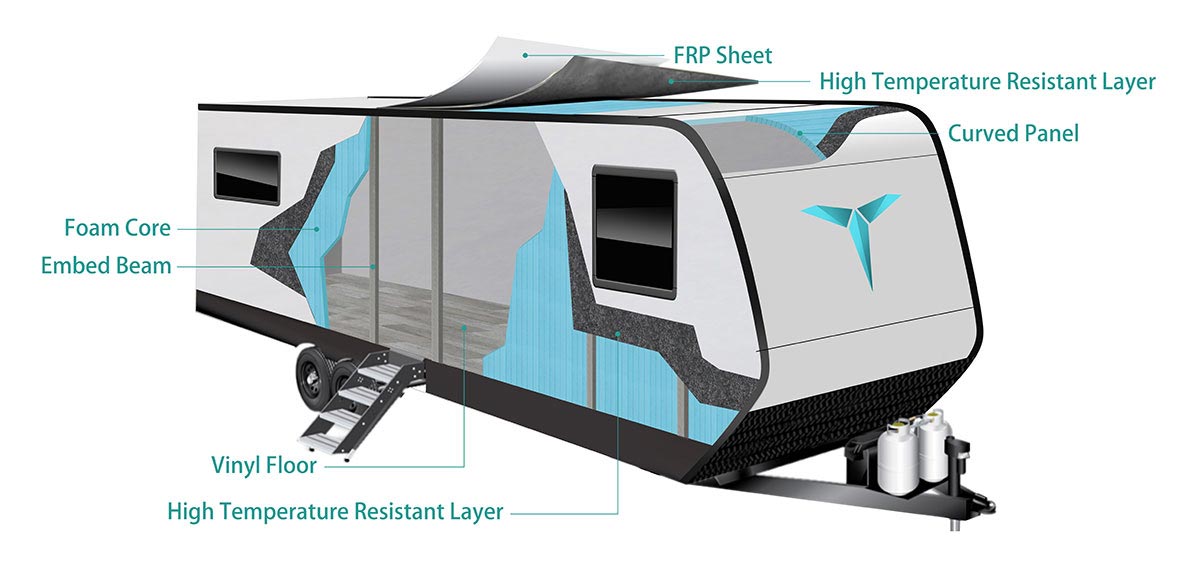

Fibreglass Composite Panels for Caravans

- One-piece Composite Panels

- Embedded Frame Structure

- CNC Machining Services

- Lightweight & Strong

- Waterproof & Moistureproof

- Longer Service Life

FRP/GRP Sheets

What is FRP/GRP?

Before understanding fibreglass composite panels, let’s first understand FRP/GRP (fibreglass reinforced plastic), It is a composite material that uses fiberglass products (fibreglass cloth/tape/felt/yarn, etc.) as reinforcement materials and synthetic resins (unsaturated polyester, epoxy resin, phenolic resin, etc.) as matrix materials.FRP has many advantages, such as lightweight, high strength, waterproof, corrosion resistance, electrical insulation, heat insulation, etc. These advantages make it the most popular skin material for RV composite panels.

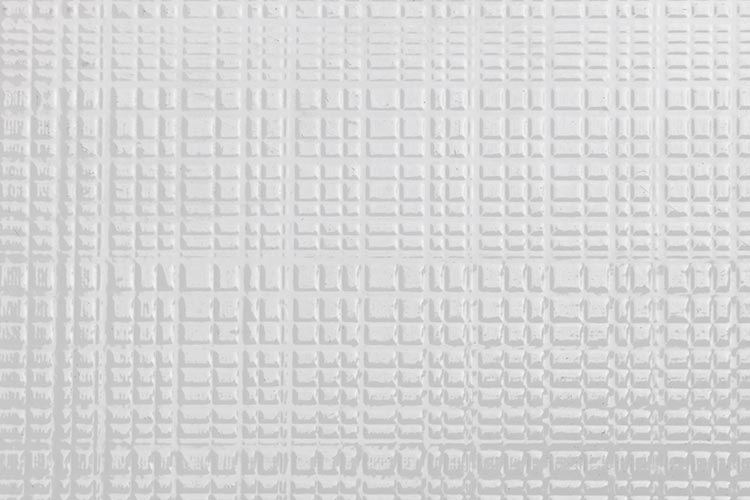

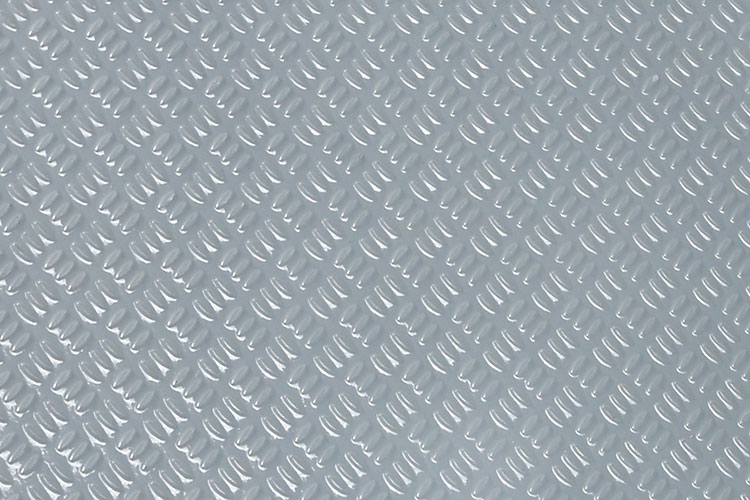

The surface of FRP/GRP can be processed into various texture patterns

Advantages of Fiberglass Composite Panels

- Lightweight: Fiberglass composite panels are much lower in density than any metal or wood siding panels.

- Strong: The fiberglass in FRP is arranged in different ways, so that it has ultra-high impact resistance, and the composite panel will not be easily deformed or damaged. Metal and wood cannot withstand higher impact forces.

- Easy to Repair: After FRP is damaged, it is very convenient to repair without leaving ugly marks, while metal and wood are difficult to repair once damaged.

- Thermal Insulation: We have a variety of foam core materials for customers to choose, such as XPS, PET, PU, PVC, these closed-cell foam boards have good thermal insulation performance.

- Fire Resistance: Our FRP for RVs has added flame retardants, and the flame retardant level has reached B1 level.

- Waterproof & Moistureproof: FRP is almost completely non-absorbent, and it can effectively prevent the infiltration of external rainwater.

- Easy to Install: Fiberglass composite panels are easy to cut, and they can be installed using simple tools.

- Longer Service Life: Our fiberglass composite panels usually have a service life of more than ten years, and the FRP will not be powdered, faded, or cracked in harsh environments.

- Aesthetic Effect: The surface of FRP will be processed according to the customer’s preference and application requirements, such as high-gloss surface, matte surface, and various colors and patterns.

The Application of Fibreglass Composite Panels in Caravans

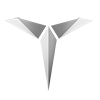

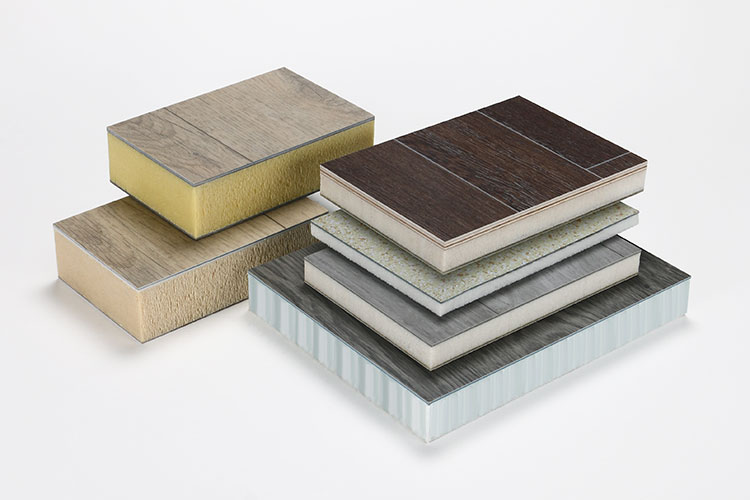

There are many advantages to using fiberglass composite panels in RVs over plywood or aluminum skin composite panels. FRP is not easy to rot, it will not rot in wet environments like wood. FRP is very light, it is lighter than the lightest metal aluminum. FRP composite panels are easy to process, whether it is cutting or assembling. The fibreglass composite panel for RV is a typical sandwich structure, which perfectly combines strength and lightweight. The upper and lower layers are gel-coated FRP sheets, and the middle is a core material. The core material is usually selected foam or honeycomb (according to application requirements). Many parts of the RV use fibreglass sandwich panels, such as wall panels, roof panels, floor panels, and furniture panels.

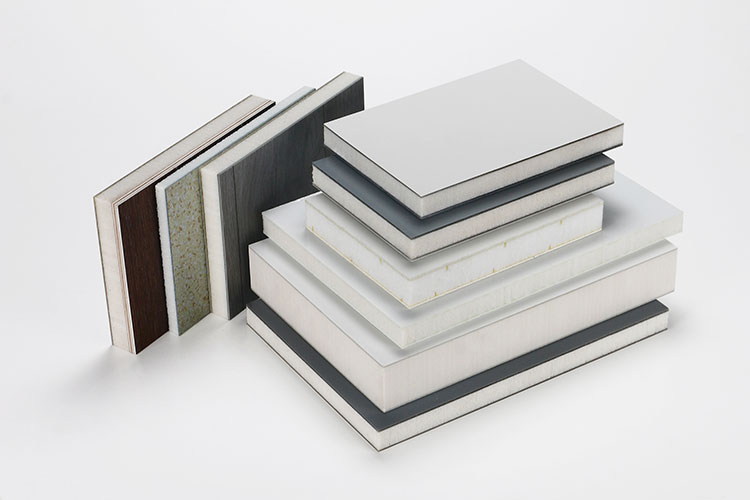

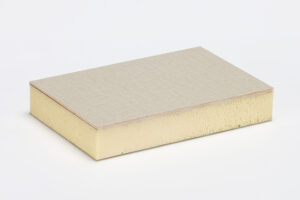

Fibreglass Foam Sandwich Panels

The core material of the fibreglass foam sandwich panel is usually selected from XPS, PET, PVC, PET, MPP, EPP, etc. The density, thermal conductivity, hardness, and water absorption of these foam materials are different. RV manufacturers choose core materials according to the application environment of the camper. For example, XPS and PU have very low water absorption and low thermal conductivity and are usually used in RVs with high thermal insulation performance. PET and PVC foams have relatively high density and hardness and are usually used in RVs with relatively high strength requirements.

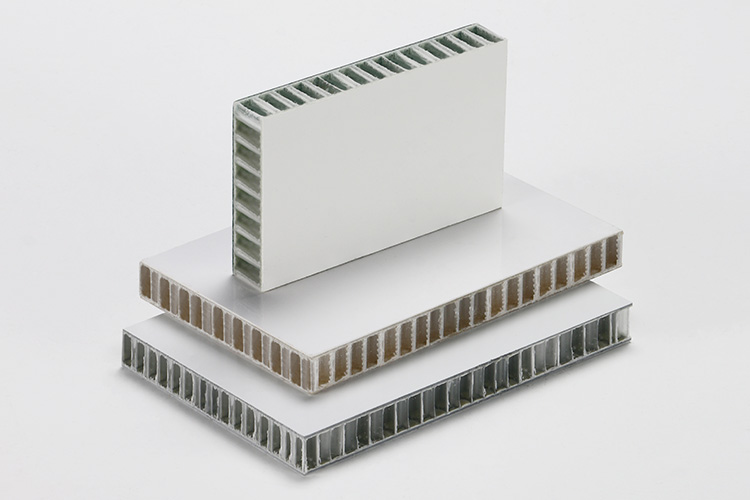

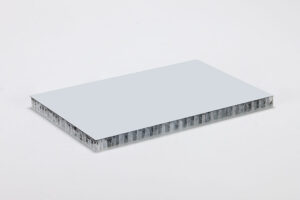

Fibreglass Honeycomb Sandwich Panels

The core material of the fiberglass honeycomb sandwich panel is usually PP (polypropylene), and the shape of the honeycomb is mostly circular holes with a diameter between 6~16mm. Compared with the fiberglass foam panel, the honeycomb panel is lighter and stronger. The skin of the commonly used fiberglass honeycomb panel is continuous fiberglass reinforced thermoplastic, which is composited with the core material by a thermal bonding process.

What Are The Highlights of TOPOLO RV Fibreglass Composite Panels?

One-piece Molding Process

Use the press to make the FRP skin and core material in the mold at one time, avoiding various problems such as delamination and uneven surface caused by manual production. The size of the RV composite panel can reach 12m in length and 3.2m in width.

Embedded Frame Structure

The embedded structure can not only enhance the strength of the RV Composite panel but also facilitate the installation of screws and the layout of electrical wire. The commonly selected embedded structure materials are aluminum tubes, stainless tubes, timbers, fibreglass tubes, etc.

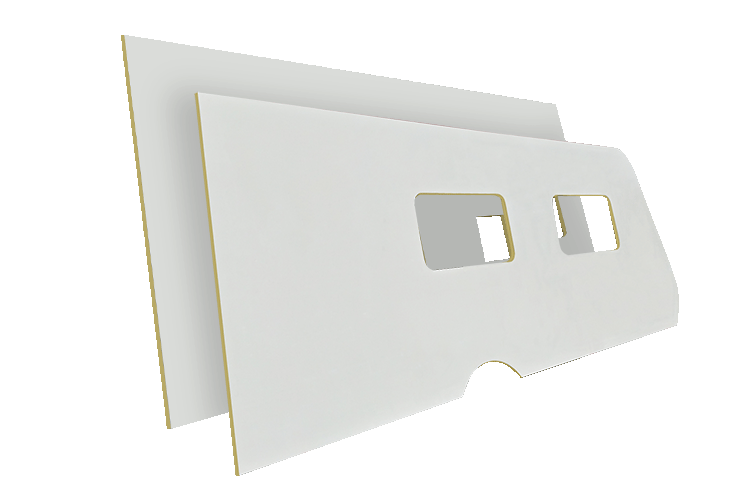

CNC Machining Services

We use advanced 5-axis synchronous CNC machines to cut, mill, and drill fiberglass composite panels, and large quantities of composite panels can maintain the same accuracy.

Get Fibreglass Composite Panel Samples

-

65mm Gray+White Surface FRP XPS Sandwich Panels for Camper

65mm Gray+White Surface FRP XPS Sandwich Panels for Camper -

65mm Mirror FRP XPS Foam Core Composite Panels for RVs

65mm Mirror FRP XPS Foam Core Composite Panels for RVs -

28mm FRP+GMT PET Foam Core RV Composite Panels

28mm FRP+GMT PET Foam Core RV Composite Panels -

40mm Gelcoat FRP Cocerd XPS Foam Sandwich Panel for Camper

40mm Gelcoat FRP Cocerd XPS Foam Sandwich Panel for Camper -

Painted PP Honeycomb Panels

Painted PP Honeycomb Panels -

17mm PET Film FRP Skin PP Honeycomb Panels

17mm PET Film FRP Skin PP Honeycomb Panels -

Melamine Film XPS Foam Sandwich RV Panels

Melamine Film XPS Foam Sandwich RV Panels -

High Density PET Foam Sandwich Panels

High Density PET Foam Sandwich Panels -

50mm XPS+PET Foam Core Sandwich Panels

50mm XPS+PET Foam Core Sandwich Panels -

FRP Skin PCV+XPS Foam Sandwich Panels

FRP Skin PCV+XPS Foam Sandwich Panels -

62mm White FRP Skin XPS Foam RV Wall Panels

62mm White FRP Skin XPS Foam RV Wall Panels -

28mm Aluminum+FRP Skin XPS Sandwich Panels

28mm Aluminum+FRP Skin XPS Sandwich Panels -

Vinyl leather PET Sandwich RV Flooring

Vinyl leather PET Sandwich RV Flooring -

Matt Surface FRP Skin XPS Foam Panels for RV

Matt Surface FRP Skin XPS Foam Panels for RV -

50mm Vinyl Leather XPS Foam RV flooring

50mm Vinyl Leather XPS Foam RV flooring -

White + Gray Gelcoat FRP XPS Sandwich Panels

White + Gray Gelcoat FRP XPS Sandwich Panels