Rigid closed-cell PU (polyurethane) foam is one of the most ideal thermal insulation materials. Its thermal insulation effect far exceeds that of XPS (extruded polystyrene), PET (Polyethylene terephthalate), PVC (Polyvinyl chloride), EPS (Expanded Polystyrene) , rock wool and other types of foam materials. PU sandwich panels are especially suitable for RVs that require high thermal insulation.

Advantages of PU Sandwich Panels for RV

- Thermal insulation

The thermal insulation performance of rigid PU foam board is far superior to XPS, EPP and other foams, and its thermal conductivity can reach 0.017-0.022W/m.k.

- Waterproof & moistureproof

The closed cell rate of PU foam board is more than 97%, so it has excellent waterproof function. Polyurethane foam can well protect the furniture and equipment inside the RV from rain, snow, frost and dew.

- Flame retardant

Rigid PU foam is self-extinguishing when it is away from fire, and this flame-retardant performance greatly improves the safety performance of the RV.

- Lightweight

The density of most polyurethane rigid foams is between 28 and 50kg/m3. RVs built with PU sandwich panels are undoubtedly lighter, which greatly saves fuel.

- High Strength

Most of the surface materials used for the PU sandwich panel of the RV will choose FRP or aluminum, which makes the RV have high impact resistance.

Physical Properties of PU Foam Board

| Items | Unit | Value |

| Density | Kg/m3 | 35~300 |

| Compression Strength | Mpa | ≥0.15 |

| Closed Cell Rate | % | ≥97 |

| Thermal Conductivity | W/m·K | 0.017~0.022 |

| Water Absorption | % | ≤0.2 |

| Operating Temperature | ℃ | ≤100℃ |

Basic Specifications of PU Sandwich Panels for RV

| Width | Max 3.2m |

| Skin Thickness | 0.7~3mm |

| Core Thickness | 25~120mm |

| Skin Materials | FRP Sheets, Aluminum Sheets, Plywoods, Vinyl, etc. |

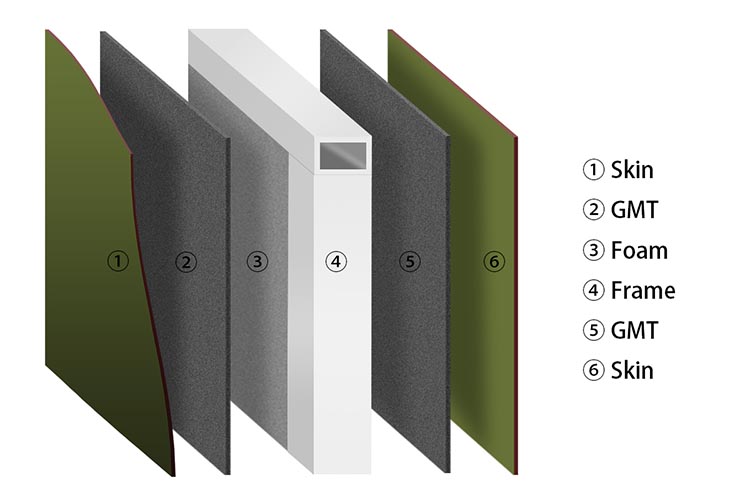

One-Piece Molding Processing

Our foam core caravan composite panels are processed in one piece. First, the frame structure (aluminum or steel pipe) of the caravan will be built. After the frame is formed, the foam core is placed and finally the core with the frame is pressed together with the skin material. Sometimes a layer of GMT (glass mat reinforced thermoplastics) material is added between the skin and the core in order to increase the strength and surface smoothness of the panel.

Fiberglass Skin PU Sandwich Panels

The surface of FRP for PU sandwich panels has a layer of gel coat with excellent performance, which makes the surface of FRP smooth and bright, and has good weather resistance to the atmosphere, water and general concentrations of acids, alkalis, salts and other media.

Aluminum Skin PU Sandwich Panels

Using high-quality PTFE, PVDF, and FEVE pre-coated alloy aluminum sheets, the surface of the panel can maintain bright colors all year round. The aluminum sheet and PU foam are bonded together with environmentally friendly polyurethane glue, which can effectively prevent the panels from degumming, cracking, and bulging.

What types of campers are PU Sandwich Panels suitable for?

PU sandwich panels are basically suitable for any type of camper wall panels regardless of cost. If your RV is used for camping in cold areas, PU foam panel is the best choice.