RV Composite Panels

- Lightweight

- High Strength

- Thermal Insulation

- Waterproof

- One-piece Molding Processing

- CNC Machining

TOPOLO-RV – Top RV Composite Panel Manufacturer

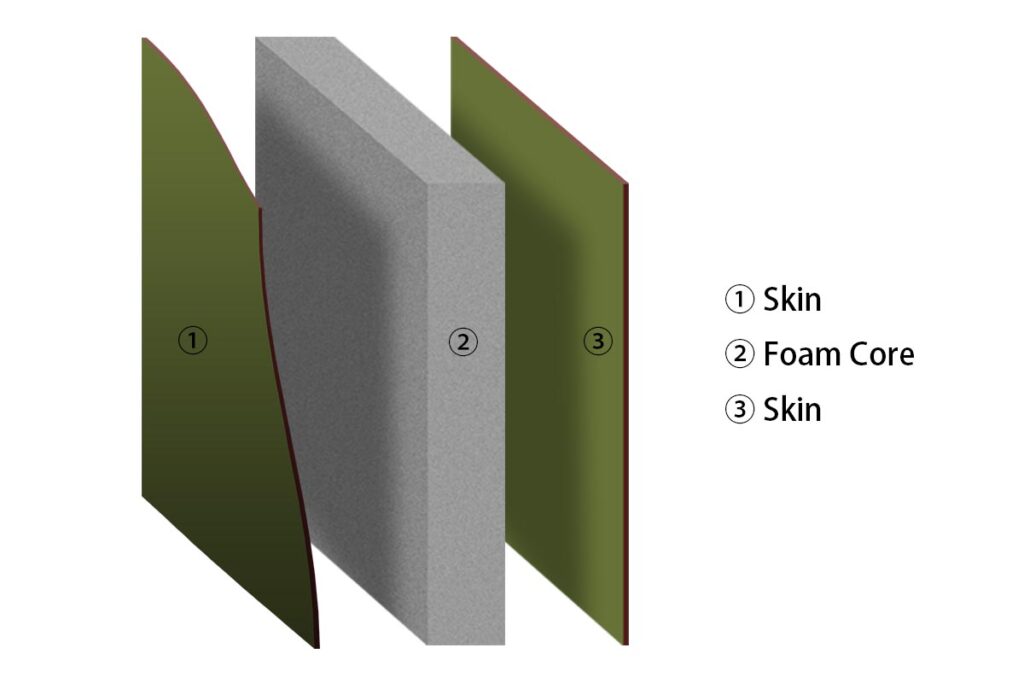

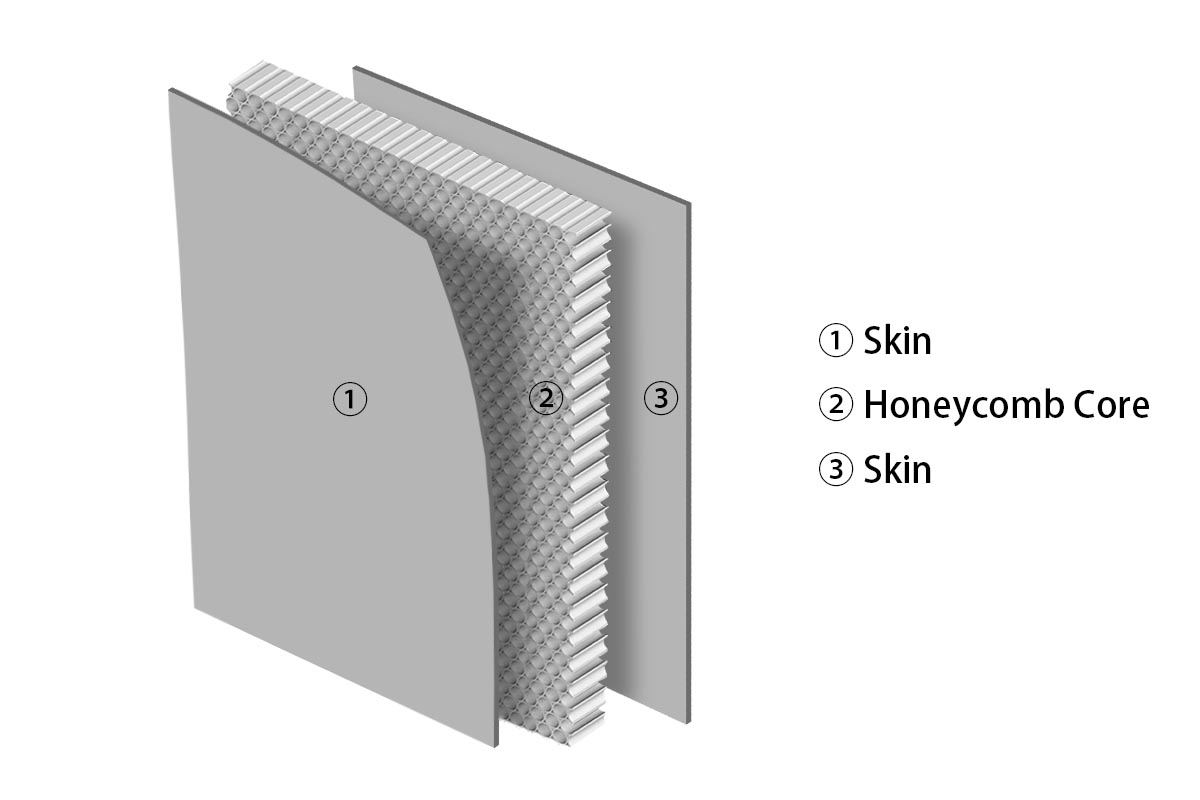

Composite panels for RVs are a factor that buyers are particularly concerned about. Although this factor does not account for a high proportion, it is an area that manufacturers should strengthen. As a product that has both eating and living functions, the stability of an RV determines its performance and durability. The side panels, roof panels, floors, front and rear panels that support the entire RV play an important role. TOPOLO-RV offers customized RV composite panels for your RV. These panels are a classic sandwich structure that is both strong and lightweight, with properties that far exceed those of traditional metal and wood. Currently, TOPOLO-RV mainly provides foam core and honeycomb core caravan composite panels. Usually, the surface skin materials are fiberglass (GRP/FRP), aluminum, and plywood.

Basic Specifications

- Core material: XPS/PET/PU/PVC foam board, PP honeycomb.

- Skin material: GRP/FRP sheets, CFRT sheets, Aluminum sheets, Plywood.

- Length: ≤12.0m.

- Width: ≤3.2m.

- Thickness: 10~120mm.

Application of Composite Panels in RVs

Our RV composite panels are one-piece sandwich panels. The advantages of this kind of composite board are lightweight, high strength, waterproof, wear-resistant, good thermal insulation effect, and easy and quick assembly.

Our custom composite panels are used in:

- RV roof.

- RV side wall.

- RV front and rear.

- RV flooring.

- RV partitions.

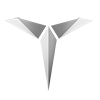

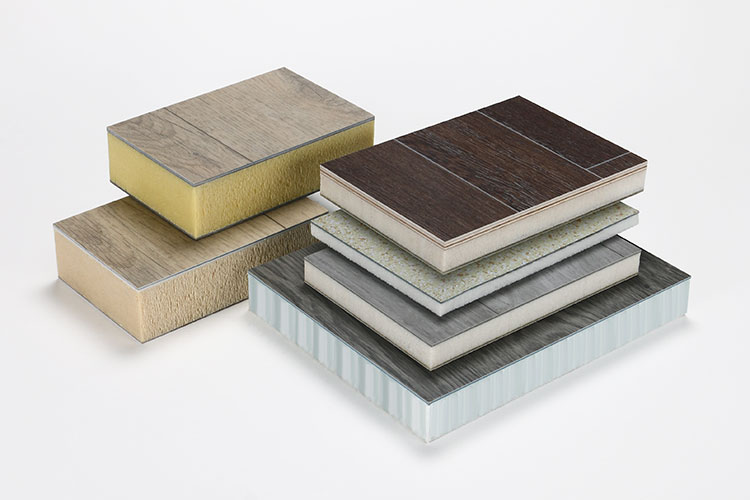

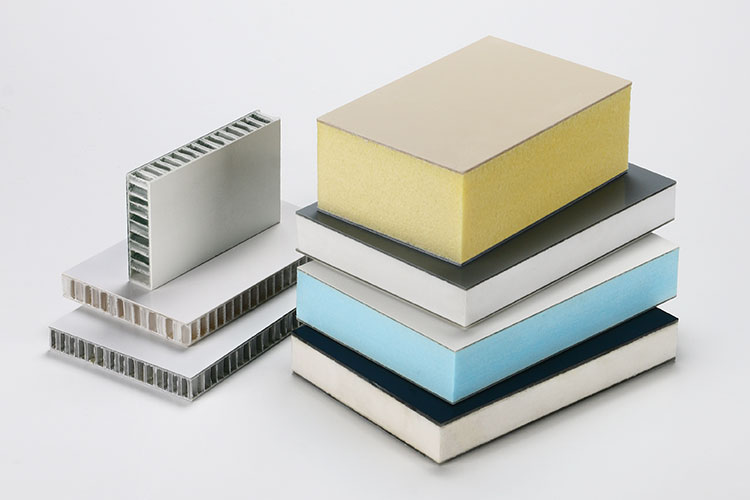

Foam Core RV Compsoite Panels

- Skin: GRP Sheets, CFRT Sheets, Aluminum Sheets, Plywood.

- Core: XPS/PU/PET/PVC Foam.

Foam board is the most common core material for RV sandwich panels. The core material is usually XPS, PU, PVC, PET foam board, etc. These rigid foam boards have excellent properties such as thermal insulation, waterproofing, and pressure resistance. The core and skin are bonded together with high-performance glue. In order to increase the strength of RV composite panels, usually, most foam core sandwich panels will have some reinforced structural components embedded inside, such as aluminum profiles, steel pipes, timbers, fiberglass components, etc.

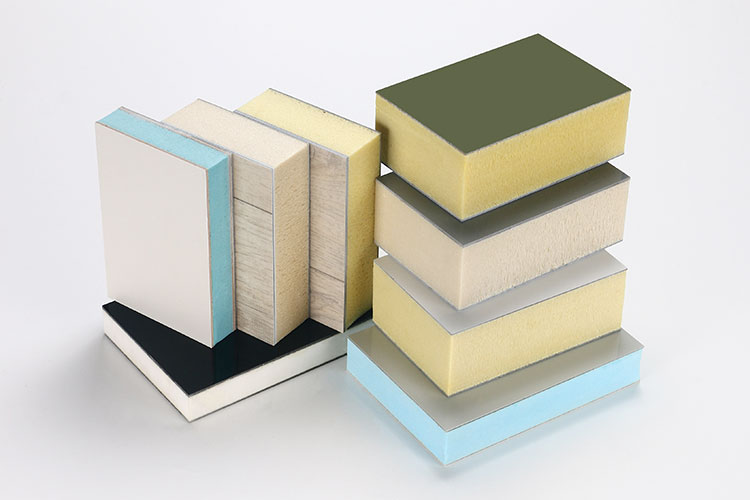

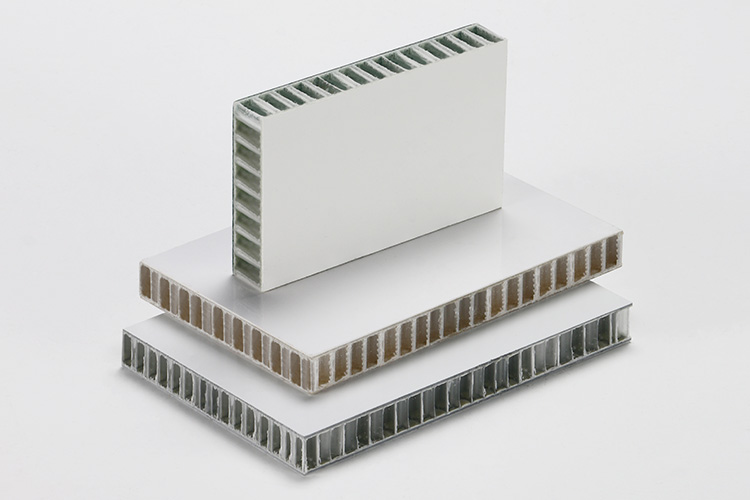

Honeycomb Core RV Wall Panels

- Skin: GRP Sheets, CFRT Sheets.

- Core: PP Honeycomb.

Most RVs using honeycomb core sandwich panels do not have high requirements for thermal insulation performance but have high requirements for material strength and lightweight. TOPOLO-RV honeycomb panel core material uses high-quality PP honeycomb, and cladding material uses multi-layer continuous fiberglass reinforced materials (CFRT). Its special feature is that the bonding of cladding and core materials does not use glue, but uses a unique hot-melt lamination process.

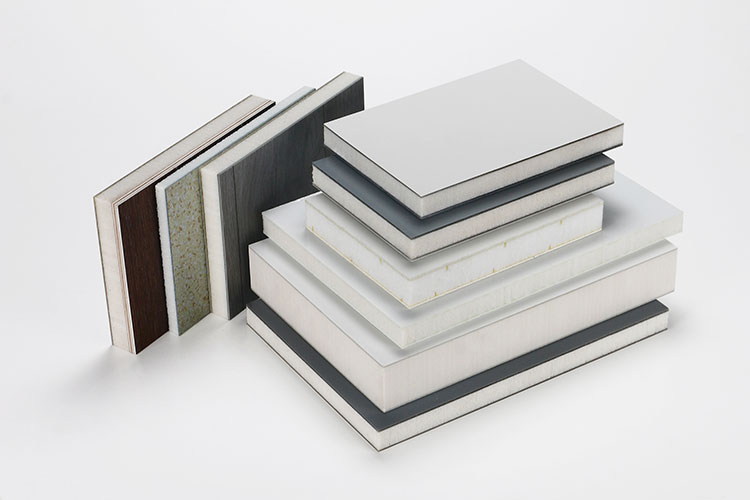

Fiberglass RV Composite Panels

Usually, fiberglass sandwich panels have a three-layer structure, with the middle layer being a core material layer (foam or honeycomb core), and the upper and lower layers being fiberglass reinforced plastic sheets (sometimes an isolation layer is added between the core material and skin to increase strength). Nowadays, fiberglass sandwich panels are becoming more and more popular in RVs and have many advantages over traditional metal or wood.

Custom RV Composite Panels for Your RV Projects

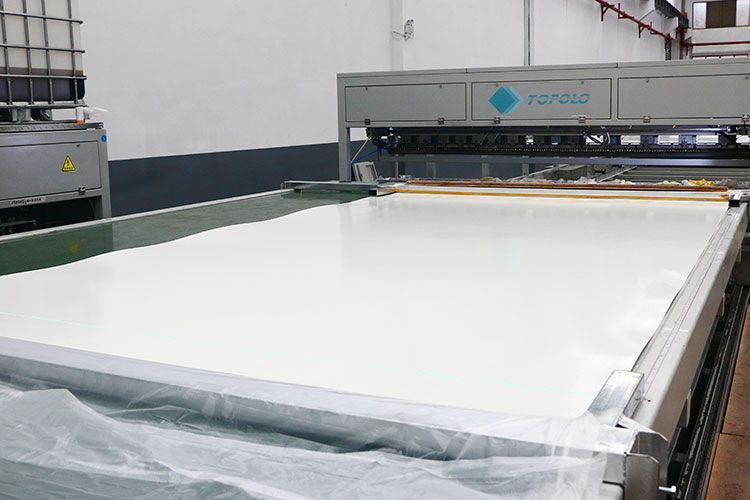

One-piece Molding Processing

Use the press to make the FRP skin and core material in the mold at one time, avoiding various problems such as delamination and uneven surface caused by manual production. The size of the RV composite panel can reach 12m in length and 3.2m in width.

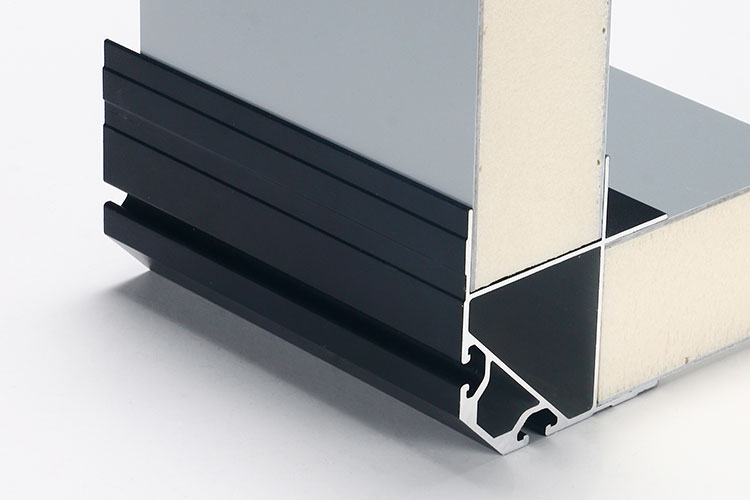

Custom Accessories

To better combine the RV panels, we customize professional metal extrusion profiles for you.

Custom Skin Patterns

To make your caravan more personalized, we customize various surface treatments for your RV composite panels.

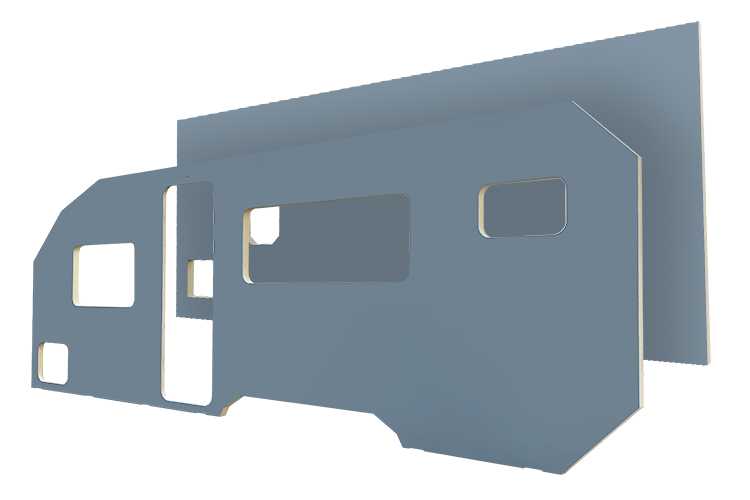

CNC Machining

According to your design drawings, we use professional CNC machines to cut out the shape of the RV panel.

TOPOLO RV Composite Panel Factory

High Quality Raw Materials

We have adopted an automatic uncoiler, which can quickly replace the material of the inner and outer skins. While cutting, the inner and outer skins are cleaned and treated to increase the bonding force with glue.

High-precision Positioning System

We use a high-precision positioning system to ensure the position accuracy of the composite panels. The cleanliness of the platform is checked before each production to ensure that no dust or particles affect the quality of the product.

Automatic Glue Spraying Machine

We use high-quality one-component polyurethane foam glue. The one-component glue reacts with water mist to produce foaming bonding between two layers of materials, which can fill small gaps and make the surface of the sandwich panel smoother. It can also make the foam sandwich panel have better toughness and improve the impact resistance of the panel.

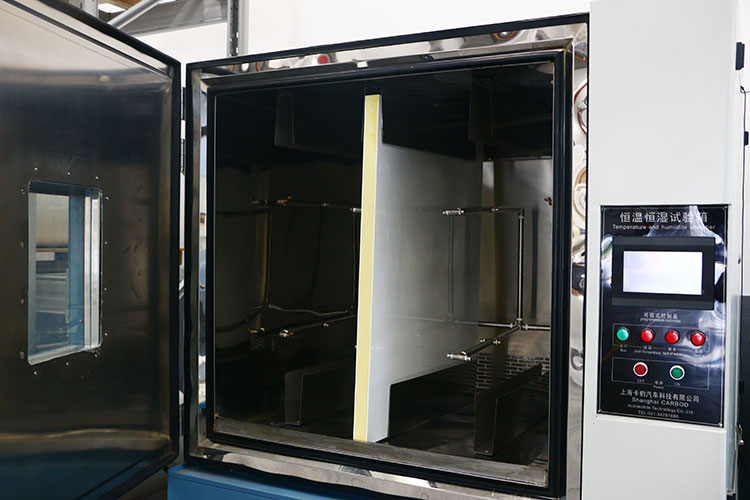

Quality Inspection

Engineers will test the cut samples, we will test the bonding strength of the panels, and analyze the pressure, bending, and peeling of the panels.

Cutting, Drilling, Grinding.

After the sandwich panel is placed for 2-3 days, the glue curing reaction has reached a state where the composite panel can be cut. Workers shape the panels into the customer’s desired shape and polish the surface.

Packaging & Transportation

Engineers design the packaging shelf according to the shape, size, and weight of the product, which not only can better protect the product but also facilitate customers to unload the product.

FAQ

Q: Do you have own factory?

A: Yes, we have our factory. Our factory covers an area of tens of thousands of square meters. Our factory is located at No. 2737, Huancheng South Road, Tongxiang City, Zhejiang Province.

Q: If I want the price, what information should I provide you?

A: You need to provide us with the material, size (length, width, height and panel thickness) and quantity of the RV body, and provide the design drawing as much as possible.

Q: Will you provide samples?

A: Yes, we will provide free samples, but customers need to bear the international express cost.

Q: How long is your delivery time?

A: It is generally within 4 weeks from the establishment of the contract to the completion of the product, and the transportation time depends on the distance between the destination country and the departure port.

Q: What payment methods do you accept?

A: We accept L/C (Letter of Credit), T/T (Telegraphic Transfer), Paypal, cash and other payment methods. In principle, we mainly accept T/T.