Australian Caravan Body Solutions

RVing and camping remain the most valuable and accessible holiday options in Australia, especially for Australian families. It can very well help consumers to escape from the city and rush to distant wild scenes. Australian-made Caravans are known for their ruggedness and durability and can adapt to some of the more complex terrains. This requires Caravan manufacturers to provide stronger materials and lightweight structures.

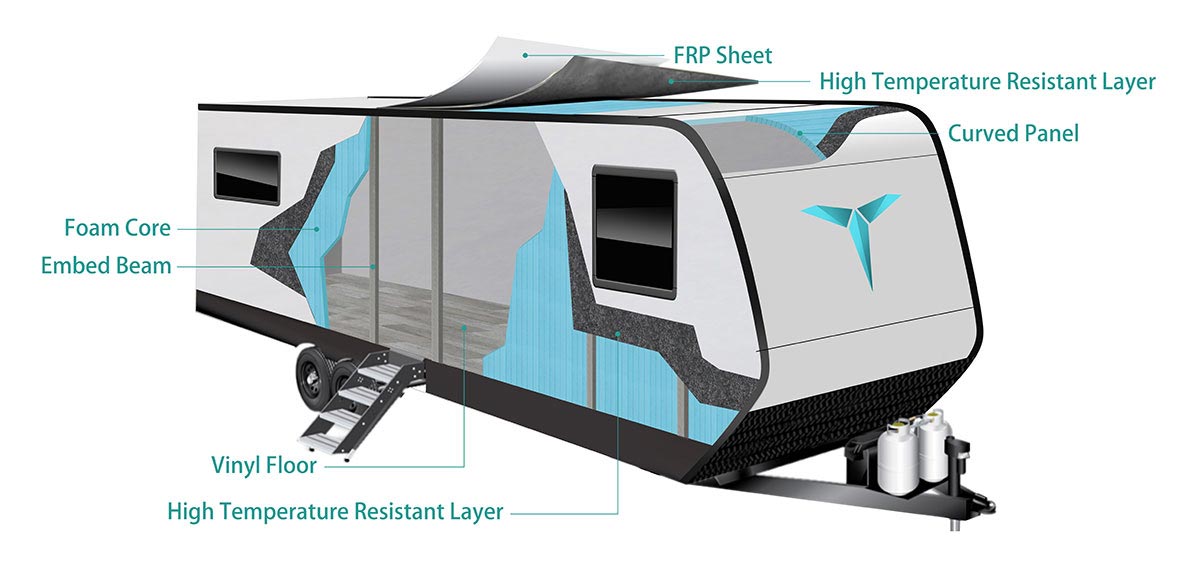

TOPOLO caravan composite panel manufacturing technology has been widely recognized by the Australian RV market. So, how does TOPOLO do it? Next, let us carefully analyze the caravan body box made of TOPOLO composite panels.

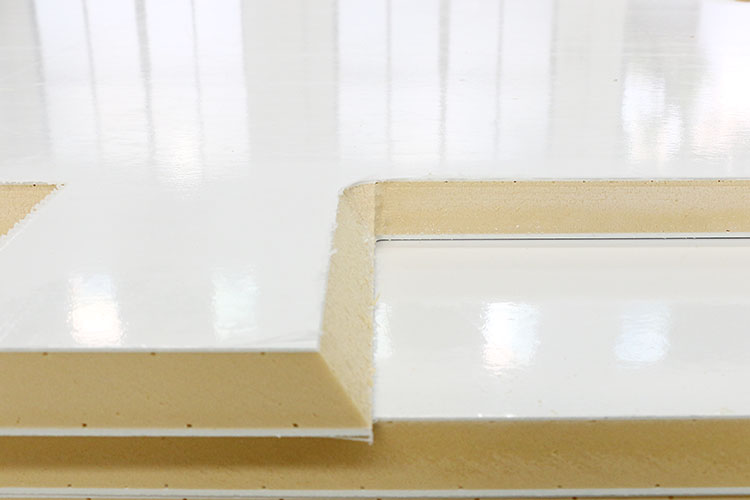

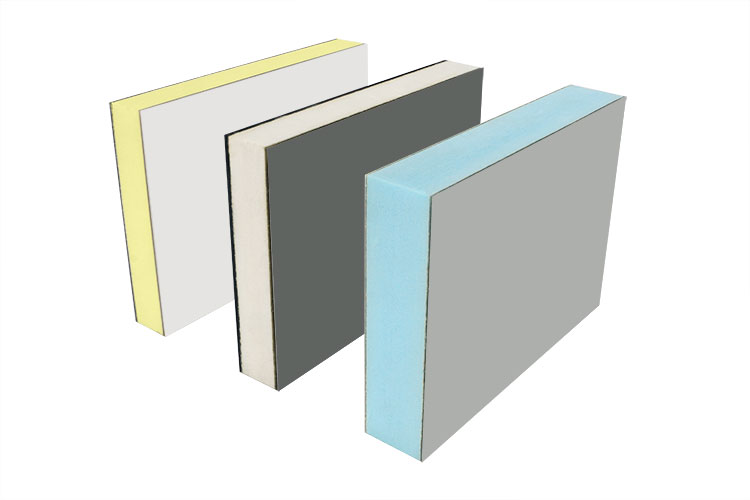

High-quality Caravan Composite Panels- FRP Sandwich Panels

TOPOLO caravan panel uses FRP sandwich panels, which use panels that combine FRP and foam core, which can not only reduce the weight of the caravan body but also increase its thermal insulation effect. Compared with traditional frame structure RVs, the advantages of FRP RV composite panels are reflected in:

- Lightweight: The weight of the RV body using FRP sandwich panels is more than 30 to 50% lighter than that of traditional wooden or metal panels.

- More aesthetic: The surface of FRP is smooth and flat, and the colors are rich and diverse.

- Waterproof: FRP can completely isolate moisture. The closed-cell foam used inside the panel does not absorb water. Its structure is stable and its service life is long.

- Easier to process and maintain: FRP panels are easy to cut and can be processed into various shapes; FRP can be quickly repaired after damage.

One-piece Caravan Composite Panel Technology

TOPOLO uses one-piece RV composite panel production technology. The skin and core materials are formed into composite panels on a vacuum press at one time. The adoption of one-piece composite panel production technology improves production efficiency, product accuracy, and product qualification rate, and also facilitates rapid assembly. Our technical advantages are reflected in:

- Large-size panel: The 144㎡ operating platform allows the original size of our RV panels to be up to 12m long, meeting the size requirements of all existing caravans.

- High precision: Using the aerospace positioning operating system and 5-axis synchronous CNC machining, the error is reduced to less than 0.5 mm.

- High strength: Using vacuum compression technology, the skin and core materials can be more closely combined.

Our Caravan Solution Recommendations

After years of production experience and long-term inspection of the Australian RV market, as well as adopting suggestions from many customers, TOPOLO has summarized numerous caravan manufacturing solutions.

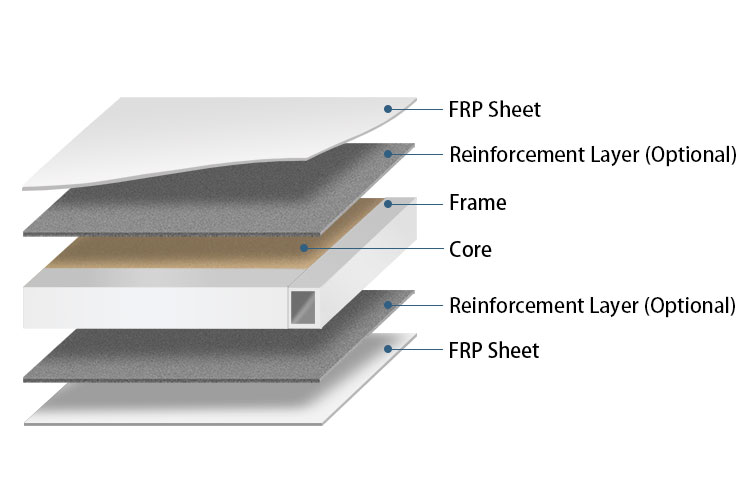

Caravan side and roof panels

High-gloss FRP XPS foam sandwich panels. In order to enhance the strength of the RV panel, we embed structural materials of various materials inside the panel. In order to obtain higher impact strength, a layer of reinforcing material is added between the skin and the core material.

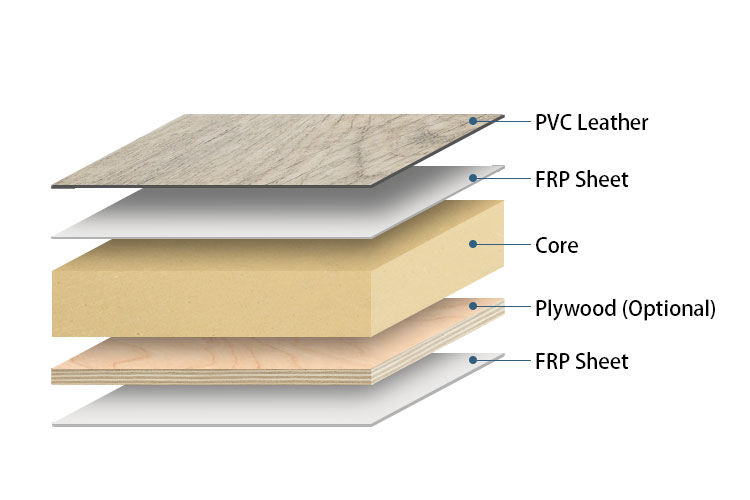

RV floor

PVC leather facing sandwich panels. The use of PVC leather-faced sandwich panels instead of traditional solid wood floors not only reduces the weight of the floor, but also combines the advantages of waterproofing and thermal insulation. The most important thing is that it will not deform and rot like wooden boards, and its service life will be longer.

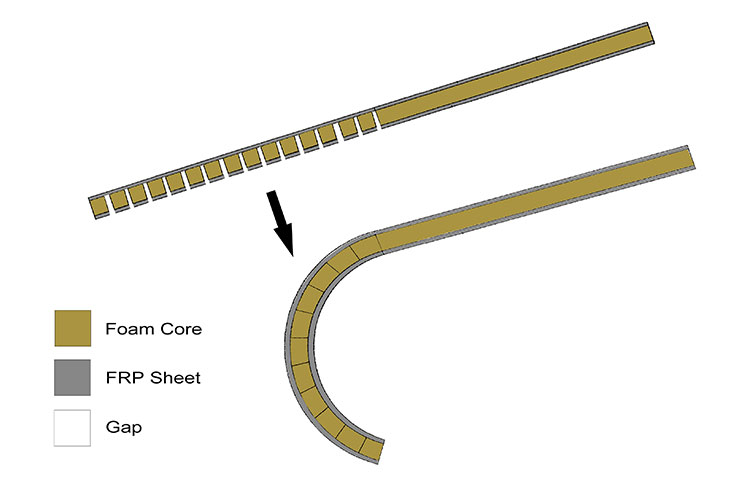

Front and rear

Curved panels. We use the method of cutting grooves to create curvature in the panels to replace mold production. This not only simplifies the production process and reduces manufacturing costs, but also retains the thermal insulation performance and strength of the composite panels.

Packaging and Shipping of RV Panels

Packaging and transportation issues have always been a concern for overseas customers. Whether the product reaches its destination safely depends directly on the safety of its packaging. How does TOPOLO achieve safer packaging and transportation?

- Pay attention to every packaging detail: We strictly abide by the regulations of the packaging process and are meticulous in every packaging detail, and our factory has achieved a smoke-free and dust-free packaging environment.

- Packaging materials are sufficient and strong: we use steel frames, fumigated wood, packaging foam, packaging film, waterproof paper and other materials to ensure that our products are fully protected.

- Customized packaging design: TOPOLO customizes a professionally proven packaging design for each customer’s product to avoid damage during transportation and facilitate unloading.